Understanding the Operation and Key Features of Cosmetic Tube Filling Machines

A cosmetic tube filling machine helps you put products into tubes. It works fast and fills each tube carefully. These machines can fill many kinds of tubes. They are used for things like facial creams, shampoo, and toothpaste. Some machines can fill watery toners. Others can fill thick pastes or medium lotions. The market for these machines was worth $1.2 billion in 2024. It is expected to keep growing each year. If you need help with cosmetic tubes, Xinfly Packaging can guide you. You should learn how the machine works. You should also know which features are important for you.

- Common products filled by cosmetic tube filling machines:

- Toners, oils, serums

- Shampoo, shower gel, sunscreen

- Facial creams, hair gel, toothpaste

- Pastes and specialty items

Key Takeaways

- Cosmetic tube filling machines quickly put creams, gels, and pastes into tubes. This helps make more products faster.

- Knowing how the machine works, from loading to sealing, helps you pick the best one.

- Automatic loading systems make things faster and more exact. They can fill up to 1,000 tubes every hour with few mistakes.

- Picking the right filling system, like piston or gravity filling, helps the machine work well for each product.

- Sealing methods, such as heat sealing and ultrasonic sealing, stop leaks and keep products safe.

- Make sure the machine is easy to clean and keeps things hygienic. This helps follow safety rules and keeps products good.

- Think about how much the machine does by itself when you choose. Fully automatic machines need less work and make things run better.

- Buying from a trusted brand like Xinfly Packaging gives you good support and new features for your tube filling needs.

Operation Steps

Cosmetic tube filling machines use several steps to fill and seal tubes. You should know each step to pick the right machine. This helps your products get made smoothly. The main parts of the cosmetic tube filling machine work together. They make sure the process is fast and accurate. Here is a table that shows how the workflow goes:

| Step | Description |

|---|---|

| 1 | Empty tubes go into the machine. You can do this by hand or let the machine do it. |

| 2 | The machine turns the tubes so the open ends face up. This gets them ready for filling. |

| 3 | The machine uses different filling systems. It depends on how thick or thin your product is. Each tube gets the right amount. |

| 4 | After filling, the tubes get sealed. This stops leaks. The machine can use heat, ultrasound, or pressure to seal them. |

| 5 | Other steps can happen next. These include putting on caps, adding labels, or packing the tubes. |

| 6 | The sealed tubes leave the machine. They go onto a conveyor belt or a robotic arm for boxing. |

Tube Loading

First, you load empty cosmetic tubes into the cosmetic tube filling machine. This step starts the whole process.

Manual Loading

Manual loading means you put each tube in by hand. This works best for small batches. It is good when you need to be flexible. You can look at each tube before you load it. This helps stop problems like jams or tubes not lining up. Manual loading gives you control. But it takes more time and needs more workers.

Tip: Manual loading lets you find bad tubes early. But it makes production slower.

Automatic Loading

Automatic loading uses a feeder or robotic arm. It puts tubes into the cosmetic tube filling machine for you. This way is faster and makes fewer mistakes. Automatic machines can fill and seal up to 1,000 tubes every hour. Semi-automatic machines only do 200 tubes per hour. Automatic loading is more accurate. It fills tubes with a mistake rate of just ±1%. Semi-automatic machines have a mistake rate of ±2%. You get the same results each time and save money on labor.

- Automatic loading advantages:

- Very fast (up to 1,000 tubes/hour)

- Fewer mistakes (±1% fill accuracy)

- Tubes line up the same way each time

- Less need for workers

You might have problems during tube loading. These include tubes not lining up, leaks, jams, sensor issues, and loud noises. You should check the machine often. This keeps it easy to use and fix.

Product Filling

After loading, the cosmetic tube filling machine puts your product into each tube. The main parts, like the hopper and piston, are important here.

Hopper Function

The hopper holds your cosmetic product before it goes into the tubes. It often has a stirrer. This keeps creams, gels, or lotions smooth. You need a good hopper to keep the product even and stop clogs. The hopper is easy to clean and refill. This makes it simple to use and take care of.

| Component | Function |

|---|---|

| Hopper | Holds the product before it goes into tubes. It often stirs to keep the product even. |

| Piston or Plunger | Pushes the product from the hopper into the tubes. You can change how much it pushes. |

| Filling Nozzle | Fits around the tube opening. It stops leaks and helps fill the tube right. |

| Sealing Mechanism | Seals the tubes after filling. It can use heat or crimping. You can adjust it for different tube sizes. |

Piston/Plunger Dispensing

The piston or plunger pulls product from the hopper. It pushes the product into each tube. You can change the piston to fill different amounts. This helps you fill tubes with creams, gels, or pastes. The system is accurate and does not waste product. You get the same results every time. This is important for quality.

Different filling systems work for different products:

- Gravity Filling – Good for thin liquids like toners.

- Overflow Filling – Makes clear tubes look the same.

- Piston Filling – Best for thick creams and pastes.

- Pump Filling – Works for products with different thicknesses.

- Net Weight Filling – Gives exact amounts for rules.

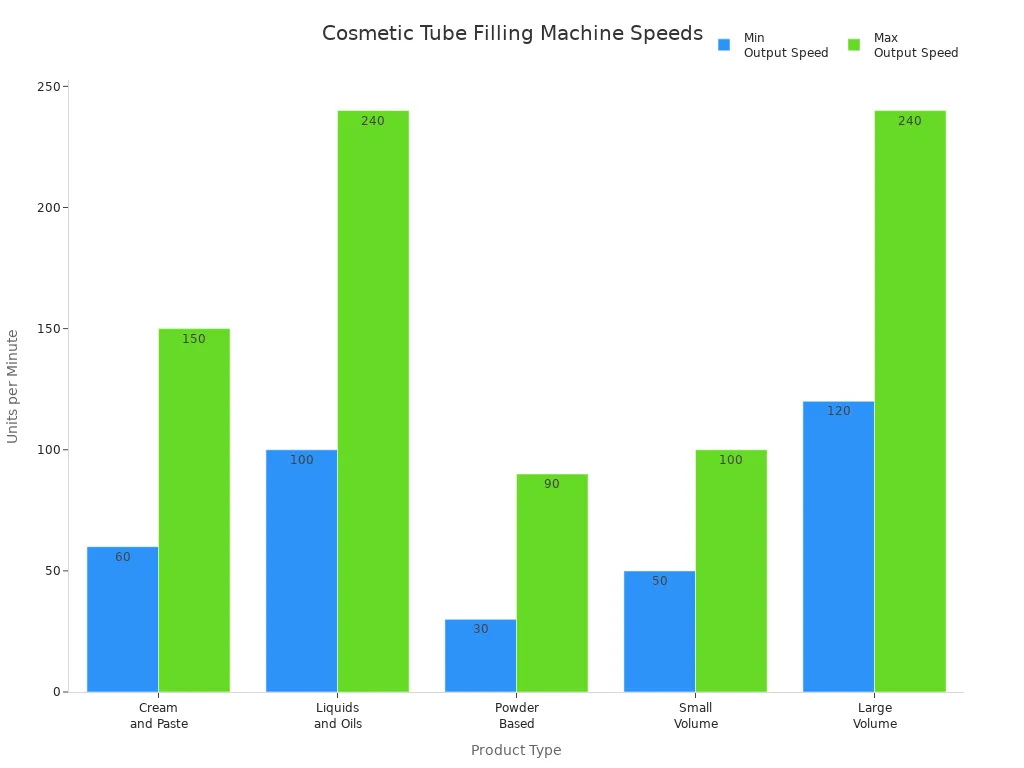

Modern cosmetic tube filling machines can fill up to 130 tubes each minute. Most work best at 100–120 tubes per minute. They fill with an accuracy of ±1%. You can see how speed changes for each product type in the chart below:

| Product Type | Recommended Machine | Output Speed |

|---|---|---|

| Cream and Paste | Paste Filler, Servo Filler | 60–150 units/min |

| Liquids and Oils | Liquid Filler, Gravity Filler | 100–240 units/min |

| Powder-Based | Auger Filler, Vacuum Filler | 30–90 units/min |

| Small Volume | Piston Filler, Tube Filler | 50–100 units/min |

| Large Volume | Multi-head Filler | 120–240 units/min |

You should pick the right filling system for your tubes. This choice affects how easy the machine is to use and clean. It also affects how good your product is.

Sealing

After filling, the cosmetic tube filling machine seals each tube. This stops leaks and keeps the product safe. The sealing method depends on your product and tube material.

Heat Sealing

Heat sealing uses high heat to melt and stick the tube ends together. You get a strong seal. But this way uses more energy and needs to warm up first. Heat sealing works well for most plastic cosmetic tubes.

| Sealing Method | Advantages | Disadvantages |

|---|---|---|

| Heat Sealing | Simple design | Uses a lot of energy and needs to warm up first. |

| Ultrasonic Sealing | Uses less energy, no warming up needed, does not hurt tubes much. | New technology and not used as much as heat sealing. |

Ultrasonic Sealing

Ultrasonic sealing uses sound waves to join the tube ends. You do not need to warm up the machine. It uses less energy. This way does not hurt the tubes much. It works well for sensitive products. You get strong seals and less machine downtime.

Crimping

Crimping squeezes the tube ends together with force. You see this way used for metal tubes or special packaging. Crimping makes a tight seal. It is good for products that need extra protection.

Note: Xinfly Packaging has cosmetic tube filling machines with advanced sealing choices. You can pick the best way to seal your tubes. This helps make the machine easy to use and take care of.

Coding

After sealing, you need to add important information to each cosmetic tube. This step is called coding. Coding helps you track your products and meet safety rules. You can print batch numbers and dates right on the tube. Many machines, like those from Xinfly Packaging, let you do this during the filling process.

Batch Marking

Batch marking puts a unique code on every tube. This code shows when and where you made the product. You can use this code to trace any problems back to a certain batch. Batch marking helps you follow the rules and keep your products safe.

| Feature | Description |

|---|---|

| Printing Capability | Some machines print batch codes and expiry dates directly onto tubes during filling and sealing. |

| Compliance | Batch marking ensures traceability and meets regulatory standards. |

Tip: Batch codes help you find and fix problems fast. You can recall only the affected tubes if needed.

Date Printing

Date printing adds the production date or expiry date to each tube. This step helps your customers know when to use the product. It also helps you follow the law. Most countries require you to print these dates on every cosmetic tube.

You must follow strict rules for coding and traceability. Here are some key requirements:

- Follow Cosmetics Good Manufacturing Practices (GMP) ISO 22716.

- Keep complete and accurate records for every batch.

- Use change control procedures to track any changes.

- Document all batches of raw materials and supplier details.

- Make sure packaging materials are safe and do not harm the product.

- Use packaging that protects the product and does not react with it.

Discharge

Once you finish coding, the machine moves the tubes to the last step. This is called discharge. Discharge means the machine collects the finished tubes and gets them ready for packing.

Finished Tube Collection

The machine pushes the finished tubes out after coding. You can collect them on a conveyor belt or in a special chute. This step keeps your process smooth and fast.

| Step | Description |

|---|---|

| 1 | Finished tubes are expelled from the machine. |

| 2 | Tubes move through the discharge unit for collection. |

You can set up the discharge area to fit your needs. Some lines use robotic arms to pack tubes into boxes. Others use workers to check and pack tubes by hand.

Quality Check

Quality checks happen during and after discharge. You or your team look at each tube to make sure it is filled, sealed, and coded correctly. You can use sensors or cameras to spot problems. If you find a tube with a mistake, you can remove it before packing.

Note: Quality checks help you keep your products safe and your customers happy. Xinfly Packaging offers machines with advanced sensors for better quality control.

By following these steps, you make sure every cosmetic tube meets high standards. You also protect your brand and follow the law.

Cosmetic Tube Filling Machine Features

When you pick a cosmetic tube filling machine, look at its main features. These features help you know which machine is best for you. There are many types of cosmetic tube filling machines. Each type has different automation, accuracy, and tube compatibility. Xinfly Packaging has machines with advanced features for cosmetic tubes.

Automation Levels

Automation levels show how much the machine does for you. You can choose manual, semi-automatic, or fully automatic machines. Each level changes how fast you fill tubes and how many workers you need.

Manual

Manual machines need you to do most steps. You put tubes in by hand and control filling and sealing. These machines are good for small batches or testing new products. You get more control, but work slower and need more people.

Semi-Automatic Cosmetic Tube Filling Machine

A semi-automatic cosmetic tube filling machine helps with some steps. You still load tubes by hand, but the machine fills and seals them. You get better speed and less waste. Semi-automatic machines are good for small and medium businesses. You can fill more tubes than with manual machines, but you still need to watch the process.

Tip: A semi-automatic cosmetic tube filling machine gives a good mix of cost and speed. You can use it for many cosmetic tube filling machine setups.

Fully Automatic

Fully automatic machines do almost everything for you. You load a batch of tubes, and the machine fills, seals, and codes them. You get high speed and need fewer workers. These machines are best for big companies that fill thousands of cosmetic tubes every day.

Here is a table that shows how automation levels change production speed:

| Automation Level | Description | Production Throughput Impact |

|---|---|---|

| Manual | You do all steps by hand. | Slow speed; needs more workers. |

| Semi-automatic cosmetic tube filling machine | Machine fills and seals; you load tubes by hand. | Medium speed; less labor needed. |

| Fully automatic | Machine does all steps; you just set it up. | Fast speed; works with little supervision. |

Filling Accuracy

You want every cosmetic tube to have the right amount inside. Filling accuracy is important. It helps you keep quality high and waste low.

Volume Control

Volume control lets you set how much goes in each tube. Volumetric fillers measure the exact amount. You get the same fill every time. This feature saves money and keeps customers happy.

- Volumetric fillers give you exact control.

- You waste less product.

- Your cosmetic tubes look and feel the same.

Pressure Consistency

Pressure consistency keeps filling smooth. The machine uses the same pressure for each tube. You get even fills and fewer leaks. This feature works well for thick creams and gels.

- Consistent pressure means no air bubbles.

- Your tubes seal better.

- You get a neat finish every time.

Tube Compatibility

You need a cosmetic tube filling machine that works with many tube types. Tube compatibility is important. It lets you use different materials and sizes for your cosmetic tubes.

Materials

Most machines work with plastic tubes and aluminum tubes. You can pick the best material for your product. This feature gives you more choices for packaging.

- Handles plastic tubes

- Handles aluminum tubes

- Fits many packaging needs

Sizes

You can use tubes of different sizes. The machine adjusts to fit small and large tubes. You get more flexibility for your products.

- Works with many tube sizes

- Fits short and long tubes

- Makes it easy to switch products

Note: Xinfly Packaging has machines that handle many tube materials and sizes. You can fill cosmetic tubes for skincare, haircare, and more.

Hygiene

Cleanability

You need a cosmetic tube filling machine that is simple to clean. Clean machines help keep your products safe and good. Most new machines use stainless steel parts. Stainless steel does not rust and is easy to wipe. You can take off parts like hoppers and nozzles for deep cleaning. Some machines have smooth surfaces with no sharp corners. This design stops product from getting stuck and makes cleaning quick.

Keeping your machine clean helps you stop contamination and follow health rules.

Cosmetic tube filling machines must follow strict hygiene rules. These rules protect your customers and your brand. Here is a table that shows the main regulations:

| Regulation | Description |

|---|---|

| GMP | Good Manufacturing Practice makes sure products are made and checked by quality rules. |

| FDA | Food and Drug Administration rules make sure products are safe and work well. |

| ISO 22000 | Food Safety Management System rules keep food safe all through the supply chain. |

Xinfly Packaging makes machines that meet these standards. You can trust your cosmetic tubes will stay safe and clean.

Sanitary Design

Sanitary design means the machine helps keep germs and dirt away. You want a machine with sealed joints and drip-proof parts. This stops leaks and keeps the product pure. Many machines use food-grade gaskets and hoses. These parts do not react with your creams or gels.

You should look for machines with parts that come off easily. This lets you clean every spot. Some machines even have automatic cleaning systems. These systems wash the inside with hot water or steam. You save time and lower the chance of mistakes.

Tip: Pick a machine with a sanitary design to protect customers and make cleaning simple.

Controls

User Interface

A good user interface helps you run your cosmetic tube filling machine easily. Most new machines have touch screens. You can see all the settings in one place. You can start, stop, and change the machine with a few taps. Clear menus and icons help you avoid mistakes.

You can also see alerts and error messages on the screen. This helps you fix problems fast. Xinfly Packaging offers machines with easy-to-use interfaces. You can train your team faster and cut downtime.

Programmable Settings

Programmable settings let you save time and fill tubes better. You can set the fill volume, speed, and temperature for each product. The machine remembers your settings for different cosmetic tubes. You can switch between products without wasting time.

Here is a table that shows important control features in new machines:

| Feature | Description |

|---|---|

| Precision filling | Uses special flow meters and weighing tech to fill tubes right. |

| High degree of automation | Automated controls mean less work for people and faster production. |

| Strong adaptability | Handles many liquid types and fits different bottles. |

| Hygiene and safety | Made from stainless steel with drip-proof design to keep things clean. |

New machines also use smart control systems. For example, PID with auto-tuning keeps fill amounts steady. Heated hoppers and temperature-controlled nozzles help keep the right thickness. Some machines use data checks to make sure you meet industry rules.

Note: Programmable settings help you keep your process steady and fast.

Safety

Emergency Stop

Safety is very important when you use a cosmetic tube filling machine. Every machine should have an emergency stop button. You can press this button to stop the machine right away if something goes wrong. This feature protects you and your team from harm.

You should always know where the emergency stop button is before you start the machine. Xinfly Packaging includes clear and easy-to-reach emergency stops on all machines.

Guards

Guards keep you safe from moving parts. These covers stop your hands or clothes from getting caught in the machine. You should never remove guards while the machine is running. Some machines have sensors that stop the machine if a guard is open.

Here is a table that lists key safety mechanisms for tube filling machines:

| Safety Mechanism | Description |

|---|---|

| Cleanliness | The parts of the filling machine must be clean and free of any debris. |

| Electrical Safety | Do not use liquids of any kind to clean the electrical components. |

| Noise Monitoring | Unusual noise from the tube filler means you should shut it down and check. |

| Hair Safety | Cover long hair whenever possible. |

| Protective Gear | Always use protective gear like work clothes, gloves, and glasses when cleaning. |

| Clothing Safety | Do not wear loose clothes or things that could get caught in moving parts. |

| Supervision | Someone must watch the machine at all times while it’s running. |

| Restricted Access | People who do not work with the machine should stay away from tube filling and sealing devices. |

Always follow safety rules. Wear protective gear and keep the work area clean. Never let untrained people near the machine.

Xinfly Packaging cares about your safety. You get machines with strong guards and emergency stops to protect your team and your business.

Cosmetic Filling Machine Benefits

When you use a cosmetic filling machine, you get many good things. These machines help you work faster and make better products. They also help you save money. Let’s see how they make your work easier.

Efficiency

Speed

A cosmetic filling machine makes you work faster. You can fill hundreds of tubes each minute. Some machines fill up to 300 tubes every minute. This is much quicker than doing it by hand. You finish big orders on time. Your customers stay happy.

- You make more products with less work.

- You finish large jobs fast.

- You keep up with what people want.

Labor Savings

You spend less money on workers when you use a cosmetic tube filling machine. The machine does most of the work for you. Your team can do other jobs. This helps your workers feel less tired. Your business runs smoother.

Cosmetic tube filling machines do the filling for you. This means you pay less for workers. You make fewer mistakes. Your products look the same every time. You can make small or big batches easily. You do not lose quality.

Consistency

Uniform Filling

A cosmetic filling machine fills every tube the same way. The machine uses smart tools to measure the right amount. Each tube gets the same fill. Your products stay high quality.

- You get the same fill every time.

- You waste less product.

- Every batch is filled just right.

Reliable Sealing

The machine seals each tube the same way every time. This stops leaks and keeps your product safe. After filling, you check each batch. You look at the weight, volume, and seal. This helps you find mistakes before your customers do.

Cost-Effectiveness

Waste Reduction

A cosmetic filling machine helps you waste less. The machine gives the exact amount needed. You do not lose product from spills or errors. This saves you money. It also helps the environment.

Savings

You save money in many ways. You pay less for workers. You waste less product. You also lose less time because the machine is easy to use and fix. Here is a table that shows why a cosmetic tube filling machine saves money:

| Factor | Explanation |

|---|---|

| Ease of use and maintenance | Machines that are simple and easy to fix help you work without stopping. |

| Filling technology and accuracy | The type of filling system changes how fast and exact the fill is. This affects waste and cost. |

| Machine flexibility | A flexible machine can change to fit new jobs. This helps you save money over time. |

| Speed and efficiency | Fast machines help you work better and save time and money. |

| Cost considerations | You should think about the price and how much it costs to keep the machine working. |

| Supplier reputation and support | A good supplier helps you fix problems and gives you good machines. This saves you money. |

When you pick a cosmetic filling machine from Xinfly Packaging, you work faster and better. Your products are always filled right. You can trust your tubes will be high quality every time.

Choosing a Cosmetic Tube Filling Machine

Production Needs

First, think about what your business needs. This helps you pick the right machine. Here are some things to think about:

- Product Type: Decide if you fill liquids, powders, pastes, or capsules. The kind of product you have changes which machine you need.

- Production Volume: Think about how many tubes you want to fill each hour. Small businesses can use manual or semi-automatic machines. Big companies may need fully automatic machines to keep up.

- Container Type: Look at the shape and size of your tubes or containers. Make sure the machine can work with your packaging.

- Accuracy Requirements: Some products, like medicine or skincare, need very exact fills. Pick a machine that gives you the accuracy you need.

- Budget: Decide how much money you can spend. Try to get the best features for your money. Sometimes paying more helps you in the future.

Machines with easy cleaning, strong safety, and simple care give you better results and value.

Feature Priorities

After you know what you need, make a list of your top features. Not every machine has the same things. You want a machine that fits your goals.

- Automation Level: Choose if you want manual, semi-automatic, or fully automatic. More automation means faster work and less help needed.

- Filling Accuracy: Find machines with good volume control and steady pressure. This helps stop waste and keeps your product good.

- Tube Compatibility: Make sure the machine works with the tube sizes and materials you use most.

- Hygiene and Cleanability: Pick machines with stainless steel parts and smooth surfaces. This keeps your products safe.

- User Controls: Choose machines with easy touch screens and settings you can change. These make it simple to switch between products.

- Safety Features: Emergency stops and guards keep you and your team safe.

Tip: Write down your three most important features before shopping. This helps you stay focused and pick the best machine.

Brand Reputation

Brand reputation is important when picking a cosmetic tube filling machine. A trusted brand helps you feel safe and get better results. Xinfly Packaging is a well-known brand in this field. They have good machines and strong support.

| Aspect | How It Affects Your Choice |

|---|---|

| Trust and Credibility | You can trust brands with a good reputation. |

| Quality | Famous brands often make better machines. |

| Sustainability | Brands that care about the planet get loyal buyers. |

| Innovation | New brands give you the latest features and tech. |

Look for brands that have a history of quality and care for customers. Xinfly Packaging is special because they focus on new ideas and helping the planet. Their machines help you reach your goals and keep your business running well.

- A good brand gives you better help and training.

- You get new features and updates.

- Your customers trust products made with high-quality equipment.

Note: Picking a trusted brand like Xinfly Packaging helps you avoid problems and build a strong business.

Support

Support is just as important as the cosmetic tube filling machine. Good support helps you fix problems fast. It keeps your work going without stops. You want a supplier who helps you before and after you buy.

Why Support Is Important

Support makes you feel sure about your choice. You know someone will help when you need it. This means you do not have long delays or big mistakes. You also learn how to use your machine better.

Tip: Always ask about support before you buy a cosmetic tube filling machine. Good support means less trouble later.

Types of Support You Should Expect

You need different support for your cosmetic tube filling machine. Here are the main types:

- Installation Help: Experts show you how to set up your machine. They help you connect and start it.

- Training: You learn how to use the machine. Training helps you and your team fill cosmetic tubes safely.

- Troubleshooting: You get help when something breaks. Support teams answer questions and fix problems fast.

- Spare Parts: You need new parts if something wears out. Fast delivery keeps your machine working.

- Technical Advice: Experts give tips for care and upgrades. Advice helps you make your process better.

What Makes Good Support?

Look for these things in a support team:

| Support Feature | Why It Matters |

|---|---|

| Fast Response | You get help quickly when you have trouble. |

| Clear Communication | You understand what to do easily. |

| Expert Knowledge | You get the right answers. |

| Availability | You can reach support any time. |

| Friendly Service | You feel good asking for help. |

Xinfly Packaging: Your Support Partner

Xinfly Packaging gives strong support for cosmetic tube filling machines. Skilled technicians help you. You get training for your team. You can order spare parts easily. You get answers about cosmetic tubes and filling technology.

Note: Xinfly Packaging knows support is important for you. You get help you can trust every step of the way.

How to Get the Most from Support

- Ask questions when you set up and train.

- Write down common problems and fixes.

- Call support as soon as you see a problem.

- Order spare parts before you run out.

- Use advice from experts to make your process better.

Support helps you use your cosmetic tube filling machine with confidence. You save time, make fewer mistakes, and help your business grow. Pick a supplier like Xinfly Packaging that cares about your needs. 😊

Industry Applications

Skincare

Cosmetic tube filling machines are important in skincare. These machines fill lotions, creams, and serums. Skincare brands like tubes because they keep products safe. Tubes are also easy for people to use. You can fill thick creams or thin serums with one machine. This lets you make many kinds of skincare products.

Here is a table that shows how tube filling machines help in skincare:

| Industry Application | Examples of Products Filled |

|---|---|

| Skin Care | Lotions, creams, serums |

You can use these machines to fill:

- Lotions for daily moisture

- Creams for night care

- Serums for special treatments

Xinfly Packaging has machines for different tube sizes and materials. You get smooth filling and strong seals. This keeps your skincare products fresh and safe.

Tip: Tube filling machines help you fill small batches for testing or big batches for stores if you want to launch new skincare products.

Haircare

Haircare brands use cosmetic tube filling machines too. You can fill shampoos, conditioners, and styling products fast. Tubes protect haircare products from air and light. This keeps them strong and ready to use.

Here is a table that shows haircare applications:

| Industry Application | Examples of Products Filled |

|---|---|

| Hair Care | Shampoos, conditioners, styling products |

You can fill:

- Shampoos for clean hair

- Conditioners for smooth hair

- Styling gels and creams for hold

Many haircare products are thick. Tube filling machines from Xinfly Packaging handle these easily. You get even fills and tight seals every time.

Note: You can switch between different haircare products without changing the whole machine. This saves you time and money.

Innovations

The cosmetic tube filling industry is always changing. New technology and trends come out every year. Smart machines help you fill tubes faster and waste less product. Automation makes your work easier and more accurate.

Here is a table with some new trends:

| Innovation/Sustainability Trend | Description |

|---|---|

| Smart Technology and Automation | Companies use smart technology and automation to keep fills even and waste less product. |

| Eco-Friendly Packaging | More brands use better packaging and biodegradable materials for cosmetics and personal care. |

| Biodegradable and Recyclable Machines | Machines are made for biodegradable and refillable packaging. |

| AI-Powered Monitoring Systems | Manufacturers use AI-powered monitoring systems to work better and waste less. |

| Digital Printing | Digital printing lets you add names or designs to each tube for customers. |

You can use machines with AI to watch filling and sealing. This helps you find problems fast. Eco-friendly packaging is popular now. You can fill tubes made from biodegradable materials. Digital printing lets you add names or designs to each tube.

Xinfly Packaging has machines with smart controls and eco-friendly options. You can follow new trends and help your business grow.

Tip: Try new features like digital printing or AI monitoring if you want to stand out. These help you make better products and protect the planet.

Sustainability

Sustainability is very important in cosmetics today. You can help the earth by picking eco-friendly packaging and machines. Cosmetic tube filling machines help your business be greener. These machines fill tubes made from recycled or biodegradable stuff. This helps you make less waste and protect nature.

Many brands use cosmetic tubes that break down or can be recycled. You can choose tubes made from sugarcane, paper, or recycled plastic. These choices help you give customers green products. Xinfly Packaging has tubes that help you reach your sustainability goals. You can ask for tubes with less plastic or tubes made from plants.

Machines that save energy help you work in a green way. You can pick tube filling machines that use less electricity. Some machines have smart controls that turn off when not needed. This saves power and lowers your bills. You can also find machines that use less water to clean. These features help you save natural resources.

Cutting waste is a big part of sustainability. You can use machines that fill tubes very accurately. This means you waste less product and packaging. You can set up your process to reuse leftover materials. Some machines let you collect extra product and use it again. This helps you save money and make less waste.

Here is a table that shows ways to make your tube filling process more sustainable:

| Sustainability Feature | How It Helps You |

|---|---|

| Recycled Tube Materials | Cuts down on plastic waste |

| Biodegradable Packaging | Breaks down safely after use |

| Energy-Efficient Machines | Uses less electricity |

| Water-Saving Cleaning | Protects water resources |

| Accurate Filling Systems | Reduces product and packaging waste |

| Reusable Components | Lowers need for new parts |

Tip: You can ask Xinfly Packaging for help with green tubes and machines. Their team helps you pick the best choices for your business.

You can teach your customers about sustainability too. You can add labels that show your tubes are eco-friendly. You can share stories about how your company helps the planet. Customers like brands that care about nature.

Sustainability gives you lots of good things. You save money, get new customers, and help the earth. You can trust Xinfly Packaging to help you reach your green goals. Their machines and packaging help you build a better future. 🌱

You now know how a cosmetic tube filling machine works. You also learned which features are important. These machines help you fill tubes fast and keep things safe. Picking the right machine helps you get better results. It also saves you money. Xinfly Packaging gives you expert help and good solutions. Think about what you need and ask professionals before you choose.

Cosmetic Tube Filling Machines – Frequently Asked Questions

A practical guide to how tube fillers work and which features matter: feeding/orientation, dosing, sealing, coding, inspection, sanitation, speed, accuracy, changeover and integration.

1) How does a tube filling machine operate from infeed to discharge?

2) Rotary vs. linear machines—what’s the difference?

3) Which tube materials can be processed?

4) What dosing systems are used and when?

5) How accurate is filling—and how is it verified?

6) What sealing options exist and how do I choose?

7) Which automation & inspection features matter most?

8) How fast can these machines run?

9) What impacts changeover time between SKUs?

10) What sanitation and compliance features should I ask for?

11) How do machines integrate with upstream/downstream equipment?

12) What utilities and footprint do I need?

13) Which QA tests should be in my validation plan?

14) What documentation should suppliers provide?

15) How do I compare quotes beyond purchase price?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.