ABL Tubes – Aluminum Barrier Laminate Tubes for Sensitive & High-Protection Formulas

ABL (Aluminum Barrier Laminate) tubes are high-barrier packaging solutions widely used for toothpaste, pharmaceuticals, cosmetics, food, and industrial products that require strong protection against oxygen, moisture, and light. At Xinfly Packaging, we supply custom ABL tubes that combine excellent barrier performance, attractive appearance, and user-friendly squeezing.

What Are ABL Tubes?

ABL tubes are a type of laminated tube constructed from multiple layers of plastic and aluminum. The aluminum layer in the middle provides a strong barrier, while the inner and outer plastic layers offer compatibility with the product and the required look and feel.

ABL tubes are commonly used for:

- Toothpaste and oral care products

- Pharmaceutical creams, ointments, and gels

- Chemical and industrial pastes

- Food products that require strong barrier protection

- Certain cosmetic or dermocosmetic formulas

They are ideal for products that are highly sensitive to oxygen, light, or humidity and need long-term stability and protection.

Advantages of ABL Tubes

1. Superior Barrier Performance

The aluminum layer provides excellent protection against oxygen, moisture, and light, helping to maintain product efficacy, flavor, fragrance, and color over the entire shelf life. This is critical for pharmaceutical, oral care, and certain food applications.

2. Extended Shelf Life for Sensitive Products

ABL tubes are designed to keep formulas stable for longer periods, reducing the risk of degradation and ensuring consistent performance from the first to the last use of the tube.

3. Good Mechanical Strength & Durability

The laminate structure offers strong resistance to puncture, cracking, and deformation during filling, transportation, and everyday use, making ABL tubes suitable for both mass-market and professional products.

4. Attractive, High-Quality Printing

ABL tubes support high-resolution printing with vivid colors and clear details. This allows brands to communicate important information and create impactful designs, even for highly technical or regulated categories like oral care and pharma.

5. Familiar Consumer Experience

Consumers are very familiar with ABL tubes in segments like toothpaste and pharmaceutical creams. The squeezable body and standard closures provide a trusted, comfortable experience for daily use.

Typical Applications of ABL Tubes

Due to their strong barrier properties and durable construction, ABL tubes are especially suitable for:

- Toothpaste & Oral Care: Fluoride toothpaste, whitening toothpaste, sensitive-care formulas, medicated gels.

- Pharmaceutical & Dermocosmetic: Prescription creams, over-the-counter ointments, medicated gels, treatment products.

- Food & Condiments: Highly sensitive sauces, flavored pastes, products that require extended shelf life.

- Industrial & Chemical: Adhesives, automotive pastes, and other technical products that must be well protected.

For brands operating in regulated or high-sensitivity categories, ABL tubes are often the preferred choice.

Custom ABL Tube Options

Xinfly Packaging offers a wide range of customization options for ABL tubes to meet specific technical and branding requirements.

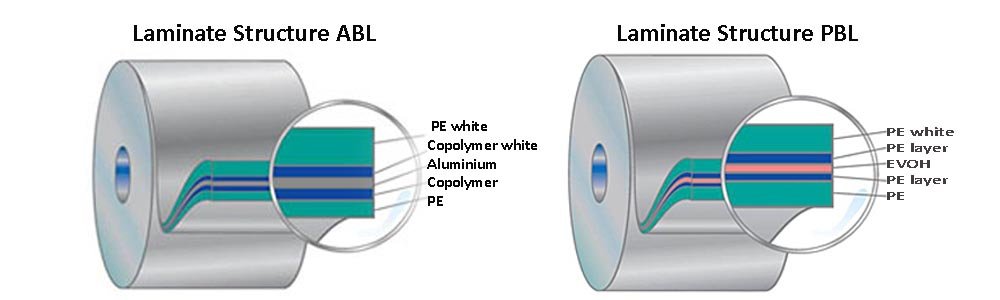

Laminate Structures

- Different aluminum layer thicknesses based on barrier needs

- Various plastic inner layers for formula compatibility

- Customized total laminate thickness to balance flexibility and strength

Diameters & Filling Capacities

Standard diameters for ABL tubes typically range from Ø16 mm to Ø40 mm, with filling capacities from about 10 ml to 150 ml. We can recommend the appropriate tube size based on your product and market.

Caps & Closures

- Flip-top caps (flat or rounded)

- Screw caps and stand-up caps

- Child-resistant or tamper-evident closures for pharmaceutical use

- Custom-colored caps to match your brand or indicate product variants

Printing & Surface Options

- High-resolution flexo or offset printing

- Silk screen printing for bold, opaque elements

- Hot stamping for premium metallic logos or details

- Matte, glossy, metallic, or soft-touch varnishes

- Registered varnish and spot effects for eye-catching design

Why Choose Xinfly Packaging for ABL Tubes?

Technical Expertise in High-Barrier Tubes

We have deep experience in producing ABL tubes for oral care, pharma, cosmetics, and other sensitive applications. Our team understands regulatory requirements and performance expectations in these markets.

Consistent Quality & Strict Control

Our production lines and quality systems are designed to ensure stable laminate quality, strong sealing, and accurate dimensions, which are critical for filling, sealing, and long-term storage performance.

Support from Development to Mass Production

From sample development and compatibility testing to full-scale production, we provide responsive service and technical support to help you launch or upgrade products with confidence.

Flexible MOQ for Different Project Sizes

Whether you are introducing a new formulation, running a pilot batch, or planning large-scale commercial production, we offer flexible minimum order quantities and competitive lead times to fit your project.