2-Layer vs 5-Layer Cosmetic Tubes What You Need to Know

You might ask why some brands use 2-layer tubes while others opt for 5-layer cosmetic tubes for their packaging. The significant difference lies in the level of protection your product receives. The materials used in the tubes and their barrier properties are crucial for keeping formulas safe, fresh, and effective. Here’s how the barrier performance of 5-layers cosmetic tubes can impact your product:

| Key Aspect | Description |

|---|---|

| Barrier Stability | Keeps formulas safe from external elements |

| Chemical Compatibility | Helps maintain high safety and product quality |

| UV Light Protection | Prevents UV light from damaging sensitive ingredients |

| Oxygen Permeability | Extends shelf life by reducing oxygen exposure |

You can count on Xinfly Packaging to provide both options for you.

Key Takeaways

- Two-layer tubes provide basic protection and are cost-effective, ideal for everyday products without strong ingredients.

- Five-layer cosmetic tubes offer superior protection with an EVOH barrier, perfect for sensitive formulas and high-quality products.

- Choosing between 2-layer and 5-layer tubes depends on your product type, needed protection, and budget considerations.

- Xinfly Packaging offers customization options for both types, allowing you to create packaging that suits your brand vision.

- Consider sustainability, as 2-layer tubes are easier to recycle, while 5-layer tubes provide better preservation but are harder to recycle.

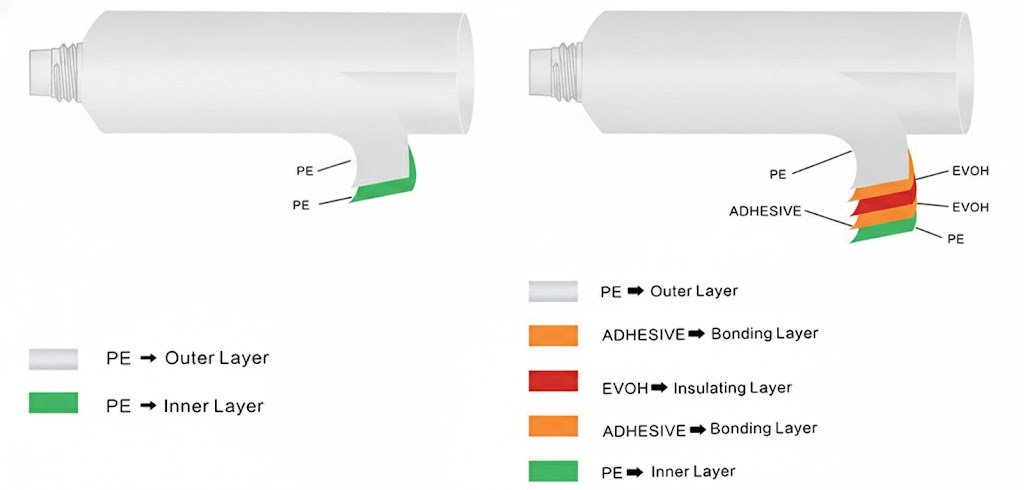

2-Layer Tubes

Structure and Materials

Two-layer tubes have a simple design. They are made with two layers of polyethylene. First, the PE resin melts and turns into a long tube shape. Workers cut this tube to the right size. Then, they make the head and cap. Printing puts your brand and product name on the tube. The last step seals the open end. This way, two-layer tubes stay strong and bend easily.

- Two-layer tubes have:

- Two layers of PE

- Light weight

- Smooth surface for printing

Features and Benefits

Two-layer tubes give basic protection for your products. They are a cheap way to package things. The PE keeps your product safe from dust and water. These tubes are good for creams, lotions, and gels that do not need extra safety. The smooth outside lets you use bright colors and clear words. You can make the tube look how you want for your brand.

Tip: Two-layer tubes are best for products with stable formulas. You can save money and still get good packaging.

Pros and Cons

It is important to know the good and bad sides of two-layer tubes. The table below shows what you need to think about:

| Implications | Recommendations |

|---|---|

| Weight loss can happen if stuff moves through the tube. | Test the materials to see if they mix with your product. |

| Your product might change or get dirty. | You can add a barrier layer like EVOH or use a polyfoil or all-aluminum tube for better safety. |

| The shelf life may get shorter, and customers may not be happy. | Always check if the tube works with your product by testing it well. |

Two-layer tubes cost less than tubes with more layers. You can change how they look and make them fast. But, these tubes do not stop oxygen or strong chemicals. Some products may not stay good for a long time.

Best Uses

You can use two-layer tubes for many products. They are good for hand creams, body lotions, hair gels, and toothpaste. If your product does not have strong oils or chemicals, two-layer tubes are a smart pick. Choose these tubes if you want to save money and do not need extra layers.

- Use two-layer tubes for:

- Everyday skin care

- Hair gels

- Toothpaste

- Sunscreen with safe ingredients

Two-layer tubes help you save money and still get good quality. They are great for simple products and fast orders.

5-Layers Cosmetic Tubes

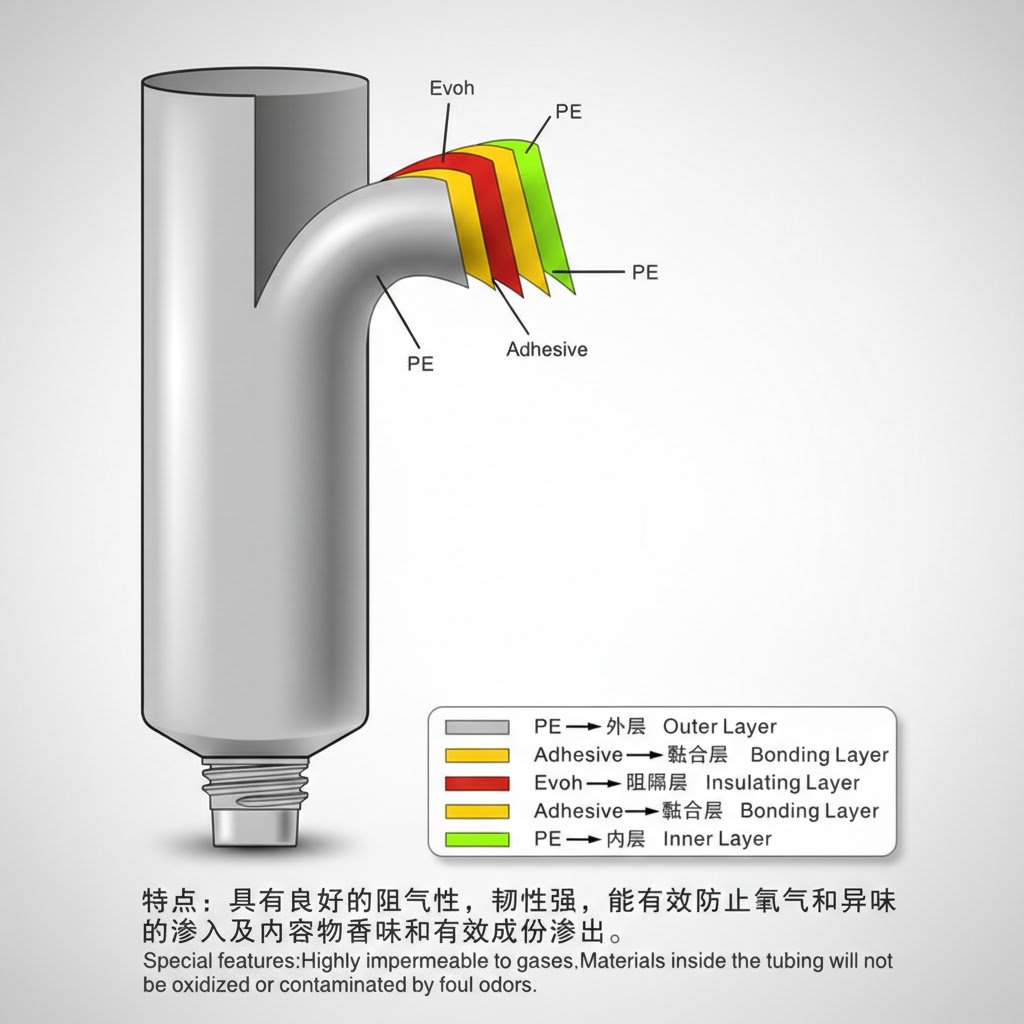

Structure and EVOH Barrier

You will find that 5-layers cosmetic tubes have a special design. These tubes use five different layers to protect your product. The most important part is the EVOH barrier in the middle. This layer keeps out oxygen, UV light, and moisture. It also stops scents and oils from escaping. Here is how each layer works:

| Layer | Material | Function |

|---|---|---|

| 1 & 5 | PE | Outer and inner surfaces, giving softness and keeping your product safe. |

| 2 & 4 | Adhesive | Holds all the layers together for strength. |

| 3 | EVOH | Blocks oxygen, UV light, and keeps in important ingredients. |

The EVOH barrier gives enhanced barrier properties. It reduces the amount of oxygen and moisture that can get inside. It also helps your product last longer and stay fresh.

Benefits of Five-Layer Tubes

You get many benefits when you choose five-layer tubes. The EVOH layer protects sensitive ingredients from breaking down. It keeps out air and light, which can damage your product. This is very important for items with vitamins, essential oils, or strong scents. The enhanced barrier properties help keep your formula strong and safe. You can trust five-layer tubes to keep your product stable and effective.

Note: Five-layer tubes work best for products that need extra care, like serums, whitening creams, and items with natural oils.

Pros and Cons

Five-layer tubes offer strong protection, but you should know both sides.

- Pros:

- They stop oxygen and moisture from getting in.

- They keep scents and oils from escaping.

- They help your product last longer.

- Cons:

- They cost more to make than simple tubes.

- They are harder to recycle because of the extra layers.

You should think about your product’s needs and your budget before you choose five-layer tubes.

Ideal Applications

You should use 5-layers cosmetic tubes for products that need the best protection. These tubes are perfect for:

- Premium creams and lotions

- Serums with antioxidants

- Products with essential oils

- Whitening or anti-aging formulas

- Items with strong scents or volatile ingredients

Five-layer tubes keep your product safe and fresh. They help you deliver high-quality results to your customers.

2-Layer vs 5-Layer Comparison

Cost Differences

You want to spend less money, but you also want your product to look nice. Two-layer tubes are cheaper than five-layer tubes. They use a simple design and fewer materials. This makes them cost less to make. You can pick two-layer tubes for products that do not need a lot of protection. This helps you save money, especially if you order a lot at once.

Five-layer tubes cost more because they use more materials. They have a special structure with extra layers. The EVOH barrier adds to the price. If your product needs strong protection or has sensitive ingredients, the higher price can be worth it. Xinfly Packaging has both types, so you can pick what works for your budget and product.

Protection and Barrier Performance

It is important to keep your product safe and fresh. Two-layer tubes give basic protection from dust and water. They are good for things like hand creams or gels that do not need much safety. But, they do not stop oxygen or strong chemicals.

Five-layer tubes protect your product much better. The EVOH barrier blocks oxygen, UV light, and moisture. This keeps your product safe from things outside the tube. It also stops smells and oils from getting out. You should use five-layer tubes for products with vitamins, essential oils, or strong scents. These tubes help your product last longer and stay good.

Tip: If your product has sensitive or active ingredients, pick five-layer tubes for the best protection.

Sustainability Impact

You want to help the planet and use packaging that is good for the earth. The cosmetics industry tries to make packaging that protects products and is better for the environment.

- Two-layer tubes use less material and can be made from plastics that can be recycled.

- Five-layer tubes protect better, but the extra layers make recycling harder.

- Some brands use split-layer packaging to make recycling easier and help the planet.

- Life Cycle Assessment studies show that tubes with one material and less barrier can be easier to recycle than tubes with many layers.

- Both types can use new materials like PCR plastics, bioplastics, or compostable options.

- You should always check if your tube matches your green goals.

Xinfly Packaging can help you choose tubes that fit your brand’s green mission. You can ask about tubes that can be recycled or refilled for both two-layer and five-layer tubes.

Customization Options

You want your product to look special on the shelf. Both two-layer and five-layer tubes let you change how your product looks. Xinfly Packaging gives you choices for size, color, and caps. You can send your own design for review before they start making the tubes.

| Customization Aspect | Details |

|---|---|

| Tube Sizes | Pick from 1oz/30ml, 2oz/60ml, 3oz/90ml, and more. |

| Artwork Submission | Send your design for a die-line review before making the tubes. |

| Minimum Order Quantities | You can start with just one case, depending on the size. |

| Cap Options | Choose black, white, or aluminum octagonal and standup caps. |

You can also try new ideas like monomaterial designs, refillable systems, or waterless products. These choices help your brand look modern and eco-friendly. Xinfly Packaging gives you the newest options for both types of tubes.

Note: Customization helps you match your packaging to your brand and product.

Side-by-Side Summary Table

Here is an easy way to see how two-layer and five-layer tubes are different:

| Feature | 2-Layer Tubes | 5-Layer Tubes |

|---|---|---|

| Cost | Lower | Higher |

| Barrier Protection | Basic | Advanced (EVOH barrier) |

| Sustainability | Easier to recycle | More complex to recycle |

| Customization | Wide options | Wide options |

| Best For | Stable formulas | Sensitive/active formulas |

| Xinfly Packaging | Available | Available |

You can trust Xinfly Packaging to help you pick the right tube. You can get simple two-layer tubes or advanced five-layer cosmetic tubes for your product.

Choosing the Right Tube

Product Type and Ingredients

Pick a tube that matches your product’s formula. Some ingredients can react with packaging and lose power. Sensitive formulas, like those with vitamins or essential oils, need strong barriers to stay fresh. Volatile ingredients might escape if the tube is weak. You should choose packaging that keeps your product safe and stable.

Here is a table to help you decide:

| Layer Type | Features | Suitable Products |

|---|---|---|

| 2 Layers | Soft, flexible, easy to use, good chemical stability, but poor barrier against oxidation | Creams, hand creams, masks |

| 5 Layers | Strong air barrier, tough, blocks oxygen and odor, protects fragrance and active ingredients | Sunscreen, depilatory cream, deodorant, ointment |

Tip: If your formula is sensitive or has active ingredients, pick tubes with EVOH or aluminum barriers. Glass or inert plastics are good for products that break down easily.

- Tubes with higher barriers protect sensitive formulas from breaking down.

- Volatile ingredients need packaging that stops leaks and keeps them safe.

Budget and Brand Positioning

Your packaging should fit your budget and brand style. The price of tubes affects how much you charge and how people see your product. Premium brands often use five-layer tubes for better protection and a fancy look. These tubes cost more but help stop product problems and make your product look valuable.

You can save money by:

- Buying in bulk to get lower prices.

- Picking standard packaging instead of custom shapes.

- Using simple decoration styles.

- Planning ahead to avoid extra fees.

It is important to balance cost, strength, and looks. Your packaging should match your brand’s goals and customers. Think about future growth and how your tube choice will affect your budget later.

| Feature | 5-Layer Tubes (ABL) | 2-Layer Tubes |

|---|---|---|

| Barrier Protection | Superior | Limited |

| Product Integrity | Enhanced | Basic |

| Aesthetic Appeal | High | Lower |

| Cost Consideration | Higher, justified by quality | Lower, higher risk |

Working with Xinfly Packaging

You can make better choices with expert help. Xinfly Packaging gives support at every step. You get advice on tube design, cap picking, and printing. Sampling lets you test your artwork and see if your product fits. Flexible order sizes help you launch new products or grow your line.

| Service Type | Description |

|---|---|

| Project Guidance | Help with tube design, cap choice, and printing options |

| Sampling Support | Artwork changes and sample tubes |

| Export Packing Coordination | Help with packing and shipping |

| Flexible MOQ Options | Small orders for launches or new products |

Note: Work with experts to avoid mistakes. Test your packaging for safety, strength, and shelf look. Make sure your tube fits your brand and follows safety rules.

Now you know 2-layer tubes are good for simple products. These tubes work well for things you use every day. Five-layer tubes are better for products with sensitive formulas. Pick five-layer tubes if your product needs more safety from air or light. Xinfly Packaging can help you choose the best tube for your needs.

- They use airless pump technology to keep your formula safe and clean.

- They also have PCR and sugarcane tubes to help cut down on plastic waste.

- New trends are refillable tubes and smart packaging that make using the product easier.

Frequently Asked Questions

Key points: 2-layer vs 5-layer tube structure, barrier protection, formula compatibility, recyclability, cost, printing, MOQ & lead time.

Q1What does “2-layer” and “5-layer” mean in cosmetic tubes?

Q2Which one provides better barrier protection?

Q3When should I choose a 2-layer cosmetic tube?

Q4When is a 5-layer tube the better choice?

Q5Is a 5-layer tube always more expensive?

Q6How do layers affect recyclability?

Q7Do 2-layer and 5-layer tubes look different?

Q8Which printing and finishing options work on both?

Q9How can I confirm which structure is right for my formula?

Q10What are typical MOQ and lead time for custom tubes?

Not sure which tube structure fits your formula?

Send your product type, fill volume, and target market — we’ll recommend 2-layer vs 5-layer and provide sampling steps within 24 hours.