How do I choose the right cosmetic tubes for my product?

Selecting the right cosmetic tube begins with understanding your product’s formula and how it interacts with different tube materials. Each option, from plastic to aluminum, brings unique benefits. For example, aluminum tubes protect sensitive ingredients from air and light, keeping your product fresh longer. The choice of tube and sealing method can affect shelf life, ease of use, and how customers view your brand.

| Tube Material | Product Performance | Consumer Satisfaction |

|---|---|---|

| Plastic | Flexible, less protection | Lightweight, customizable |

| Aluminum | Superior barrier | Premium, eco-friendly |

| Laminated | Balanced protection | Glossy, aesthetic appeal |

Key Takeaways

- Test your product formula with different tube materials to avoid issues like cracking or contamination.

- Choose tube materials like aluminum or laminated tubes for sensitive formulas to protect from air and light.

- Pick dispensing systems that match your product and customer needs to improve ease of use and reduce waste.

- Consider tube size, shape, and applicators to enhance user experience and support your brand image.

- Select eco-friendly materials and reliable suppliers to boost sustainability and ensure high-quality packaging.

Product Needs

Formula Fit

Choosing the right tube starts with your product’s formula. Every ingredient can interact differently with packaging materials. You need to make sure your formula and the tube material work well together. Even standard formulas can cause unexpected problems. For example, a liquid lipstick once caused visible cracking in low-density polyethylene tubes after three months at 40°C. This happened even though no known incompatibilities existed between the formula and LDPE. This example shows why you must test your product with the tube material before launching.

Tip: Always run compatibility tests between your formula and the tube material. This helps prevent issues like cracking, leaking, or contamination.

Common compatibility issues include:

- Product migration through tube walls, which can lead to weight loss and contamination.

- Decoration failures, such as peeling or fading of printed designs.

- Chemical reactions between the formula and the tube or its decoration.

- Physical damage, like cracking or brittleness, even when incompatibility is not obvious.

You can avoid these problems by working closely with your packaging supplier. Ask for samples and perform stability tests under different temperatures and humidity levels. Packaging stability testing checks how the tube affects your product’s physical, chemical, and microbiological integrity. Testing your product in its final packaging is the best way to ensure long shelf life and safety.

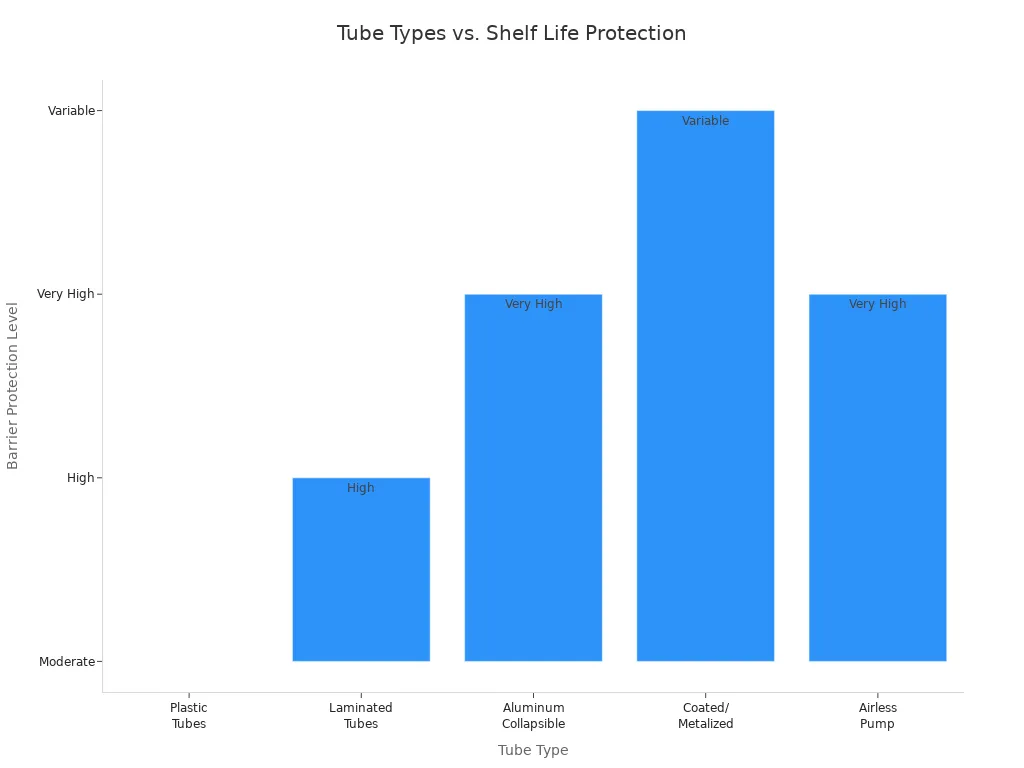

| Tube Type | Material/Design Features | Typical Product Use Cases | Impact on Shelf Life and Stability |

|---|---|---|---|

| Plastic Tubes (Mono/Multi) | LDPE, HDPE, PP; multi-layer may include EVOH | Mass-market skincare, hair care, sunscreen | Moderate barrier protection; multi-layer improves shelf life |

| Laminated Tubes (ABL/PBL) | Aluminum foil + plastic layers or multi-layer plastic | Toothpaste, pharmaceutical creams, food-grade cosmetics | High oxygen and moisture barrier, excellent for sensitive formulas |

| Aluminum Collapsible Tubes | Fully opaque, collapsible, airtight | Medicated creams, organic skincare, ointments | Prevent oxidation and light exposure, ideal for sensitive actives |

| Coated/Metalized Tubes | Metallic or glossy finish via metallization | Premium cosmetics, limited editions | Enhances aesthetic appeal; may have UV protection but higher cost |

| Airless Pump Tubes | Airtight, prevents air exposure | Anti-aging, whitening, sensitive skin products | Protects oxygen-sensitive ingredients, extends shelf life |

You should also consider if your formula contains light-sensitive ingredients. Tubes with UV protection or opaque materials, such as aluminum, help keep these ingredients stable. Airless tubes and pumps protect formulas from air and moisture, which is important for products with active ingredients like retinol or vitamin C.

Dispensing

The way your customer dispenses the product matters just as much as the formula fit. Dispensing features affect user experience, product waste, and even shelf life. You want a tube that delivers the right amount of product every time, keeps the formula fresh, and feels easy to use.

| Dispensing Mechanism | Description | Key Benefits |

|---|---|---|

| Squeeze Tubes | Flexible plastic tubes allowing easy squeezing | Precise dispensing, convenience, suitable for creams, lotions, gels |

| Airless Tubes | Tubes that prevent air exposure to protect sensitive formulations | Maintains product freshness, ideal for serums and anti-aging creams |

| Laminated Tubes | Combination of plastic and aluminum for enhanced barrier | Superior protection from moisture and oxygen, used in high-end skincare |

| Metal Tubes | Usually aluminum, durable and protective | Excellent contamination prevention, used for ointments and creams |

Pumps are popular in the skincare and beauty industry. They use a vacuum to draw the product through a dip tube, giving you precise and hygienic dispensing. Pumps work well for lotions, creams, and oils. They reduce waste and keep the product safe from air and contaminants.

| Pump Type | Mechanism | Benefits | Common Uses |

|---|---|---|---|

| Airless Pumps | Vacuum system preventing air entry | Protects product integrity, extends shelf life | Serums, creams, lotions |

| Lotion Pumps | Vacuum draws viscous liquids through dip tube | Controlled, mess-free dispensing of thick products | Body lotions, conditioners, sunscreen |

| Foaming Pumps | Mixes product with air to create foam | Lightweight application, reduces product waste | Facial cleansers, hand soaps, mousse |

Note: Studies show that consumers are 35% more likely to buy again when the dispensing mechanism is easy to use and precise. Airless pumps also reduce oxidation and contamination, which means fewer returns and complaints.

Other dispensing options include roller tubes, which use a roller ball for smooth, targeted application. These are great for eye creams and serums. They offer a cooling effect and reduce waste by delivering just the right amount. Squeeze tubes remain a classic choice for gels and creams, offering convenience and control.

Advanced dispensing features, such as portion-controlled pumps and resealable caps, help minimize waste and improve hygiene. Ergonomic designs, like larger actuators or locking mechanisms, make the tube easier to use and prevent spills.

When you select a cosmetic tube, think about how your customer will use it every day. The right dispensing system can set your product apart and keep customers coming back.

Cosmetic Tube Materials

Choosing the right material for your cosmetic tube is essential for product safety, shelf life, and brand image. Each material offers unique benefits and challenges. Understanding these differences helps you select the best option for your formula and sustainability goals.

| Material Type | Market Share / Status | Notes |

|---|---|---|

| Plastic | 64% (2025) | Most popular due to low cost, versatility, and compatibility with many formulas. |

| Laminated | >44% (2020) | Fastest growth; combines plastic and metal for enhanced protection. |

| Aluminum | Growing | Premium feel, excellent barrier, but higher cost and supply chain challenges. |

| Bio-based | Emerging | No quantified share; brands exploring for sustainability and reduced plastic waste. |

Plastic

Plastic tubes dominate the cosmetic tube market. You see them everywhere because they are affordable, lightweight, and easy to customize. Most plastic tubes use materials like LDPE, HDPE, or PP. These plastics offer good chemical resistance and protect your product from moisture.

Pros:

- Durable and impact-resistant, reducing breakage and leakage.

- Versatile designs allow for different caps, applicators, and finishes.

- Lightweight, lowering shipping costs and carbon footprint.

- Recyclable (especially HDPE and PET), supporting sustainability.

- Opaque options protect light-sensitive ingredients.

Cons:

- Some gas permeability, which can limit protection for sensitive formulas.

- Heat sensitivity in some plastics like PET.

- Less effective barrier than aluminum or laminated tubes.

Tip: Choose mono-material plastic tubes (PE or PP) for better recyclability. These tubes are widely accepted in recycling programs and help reduce environmental impact.

Plastic tubes work well for most skincare, hair care, and body care products. They offer a balance of cost, performance, and convenience.

Aluminum

Aluminum tubes give your product a premium look and feel. They provide excellent protection against light, air, and moisture, making them ideal for sensitive or luxury cosmetics.

Pros:

- Superior barrier properties keep formulas fresh and safe from contamination.

- Infinitely recyclable with no loss of quality.

- Lightweight and corrosion-resistant, reducing shipping emissions.

- Airtight closures prevent oxidation and extend shelf life.

- Supports refillable and innovative packaging designs.

Cons:

- Higher production cost than plastic.

- Prone to denting and shape retention issues.

- Environmental concerns from mining and energy-intensive production.

- Supply chain disruptions can affect availability.

Aluminum tubes suit products like medicated creams, organic skincare, and high-end cosmetics. You can use them to highlight your brand’s commitment to quality and sustainability.

Laminated

Laminated tubes combine layers of plastic and aluminum to create a strong barrier against oxygen, moisture, and light. This multi-ply structure protects sensitive ingredients and extends shelf life.

| Feature | Description |

|---|---|

| Multi-layered Structure | Superior barrier protection, preserves product integrity and efficacy. |

| Durability & Flexibility | Easy to squeeze, travel-friendly, and durable. |

| High-Quality Printability | Supports vibrant, customizable designs for strong branding. |

| Cost-Effectiveness | Lightweight and economical, reduces shipping costs. |

| Customization | Available in various sizes, shapes, and finishes. |

| UV Resistance & Airtight Seals | Protects sensitive formulas from degradation. |

| Sustainability | Some recyclable variants, but multi-material layers complicate recycling. |

Pros:

- Exceptional barrier properties for sensitive or active formulas.

- Flexible and easy to use.

- High-quality printing for eye-catching packaging.

- Customizable in size, shape, and finish.

Cons:

- Complex recycling due to mixed materials.

- Higher cost than standard plastic tubes.

- Prone to wrinkling and compatibility issues with some formulas.

Laminated tubes are perfect for sun creams, ointments, and products that need extra protection. The EVOH layer in some tubes blocks oxygen, helping prevent color changes and ingredient loss.

Bio-Based

Bio-based cosmetic tubes use renewable or biodegradable materials like PLA or kraft paper. These tubes help reduce plastic waste and support a circular economy.

Pros:

- Made from renewable resources, lowering carbon footprint.

- Biodegradable or compostable options available.

- Supports eco-friendly brand image.

- Lightweight and customizable.

Cons:

- Higher production cost and complexity.

- Limited barrier protection compared to plastic or aluminum.

- Biodegradability depends on proper disposal and consumer awareness.

- May contaminate recycling streams if not sorted correctly.

Bio-based tubes are gaining popularity as brands look for sustainable alternatives. They work best for products where environmental impact is a top priority, but you should consider their limitations in protecting sensitive formulas.

Note: Innovations in bio-based materials continue to improve performance and cost. Always check if the tube meets your product’s barrier and stability needs before choosing this option.

Size and Shape

Volume

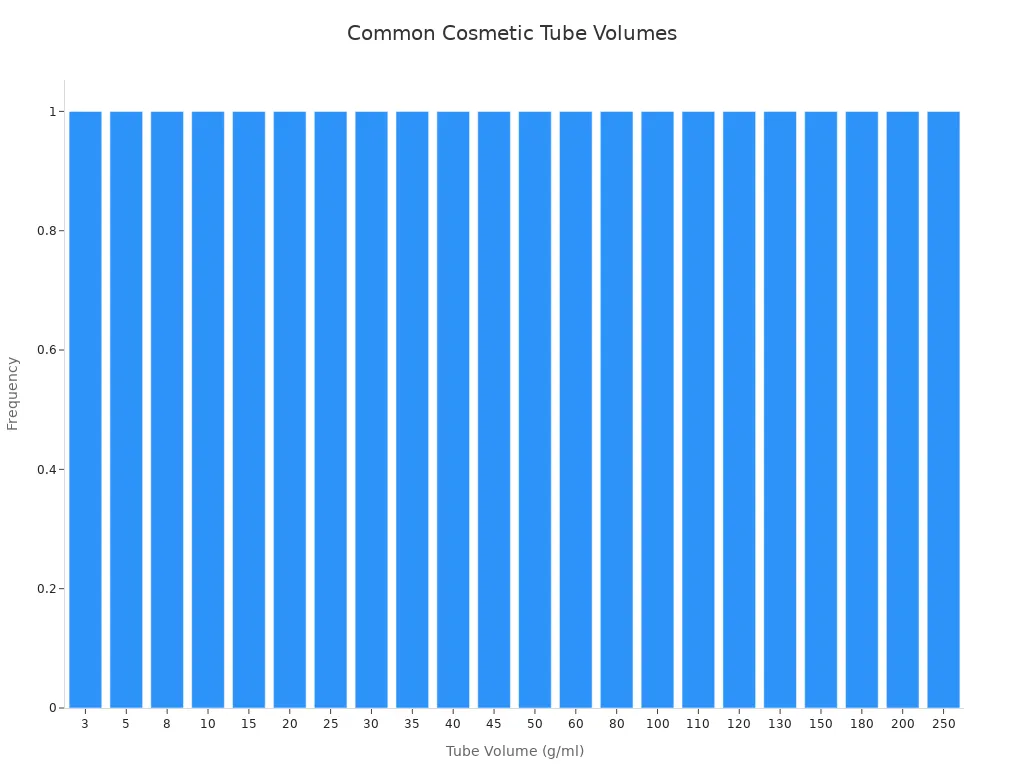

Selecting the right tube volume helps you match your product to your customers’ needs. Tube sizes in the beauty industry range from as small as 3ml to as large as 400ml. Most products use standard volumes, which makes manufacturing easier and reduces costs. You can see the most common sizes in the table below:

| Common Cosmetic Tube Volumes (g/ml) |

|---|

| 3 g/ml Cosmetic Tube |

| 5 g/ml Cosmetic Tube |

| 8 g/ml Cosmetic Tube |

| 10 g/ml Cosmetic Tube |

| 15 g/ml Cosmetic Tube |

| 20 g/ml Cosmetic Tube |

| 25 g/ml Cosmetic Tube |

| 30 g/ml Cosmetic Tube |

| 35 g/ml Cosmetic Tube |

| 40 g/ml Cosmetic Tube |

| 45 g/ml Cosmetic Tube |

| 50 g/ml Cosmetic Tube |

| 60 g/ml Cosmetic Tube |

| 80 g/ml Cosmetic Tube |

| 100 g/ml Cosmetic Tube |

| 110 g/ml Cosmetic Tube |

| 120 g/ml Cosmetic Tube |

| 130 g/ml Cosmetic Tube |

| 150 g/ml Cosmetic Tube |

| 180 g/ml Cosmetic Tube |

| 200 g/ml Cosmetic Tube |

| 250 g/ml Cosmetic Tube |

Choosing the right volume affects both how customers use your product and how much they pay. Smaller tubes work well for travel or luxury items. Larger tubes appeal to budget shoppers and reduce how often they need to buy. Standard sizes help you save on tooling fees and production costs. Larger tubes use more material, which increases cost, but they can also offer better value to your customers.

Tip: Think about your target market. On-the-go users like smaller tubes, while eco-conscious buyers may prefer larger sizes to cut down on waste.

Shape

Tube shape plays a big role in how your product looks and feels. Oval tubes are popular for skincare and beauty products because they fit comfortably in the hand. Flat extruded tubes, like those used by many brands, offer a modern look and stack easily on shelves. Precision tip tubes help with targeted treatments, such as scalp serums, by allowing controlled application. Roll-on ball tubes combine a tube with a rolling applicator, making them ideal for deodorants.

- Oval tubes: Great for general skincare and beauty.

- Flat tubes: Modern, stackable, and easy to store.

- Precision tip: Perfect for spot treatments and serums.

- Roll-on: Best for deodorants and targeted application.

Pairing the right shape with the right cap or applicator improves the user experience and supports your brand image.

Applicators

Applicators influence how your product is applied and how effective it feels. Experts agree that applicator design affects product delivery, precision, and control. Ergonomic grips and fingertip surfaces make application easier and more comfortable. Material choice, such as synthetic fibers, silicone, or foam, changes how much product is deposited and how it looks on the skin.

Soft foam applicators work well for creams and liquids, offering gentle, even coverage. Silicone applicators provide hygienic, precise application and are easy to clean. For lip gloss, you might choose a doe-foot, brush, or rollerball applicator, each giving a different feel and finish. Brands often pair specific applicators with their formulas to help customers get the best results.

Note: The right applicator can set your product apart. A well-designed applicator improves ease of use, boosts satisfaction, and encourages repeat purchases.

Customization

Printing

You can make your packaging stand out with the right printing technique. Screen printing gives you bold, durable colors that last through daily use. Many brands choose this method for its thick ink layers and ability to handle curved surfaces. Hot stamping adds a shiny, metallic finish that makes your product look luxurious and premium. If you want flexibility for short runs or detailed, full-color designs, digital printing works best. Offset printing is a smart choice for large orders because it produces high-quality, consistent prints on flat surfaces. Each method offers unique benefits, so you should match your choice to your brand’s style, product type, and budget.

| Printing Technique | Advantages | Best For |

|---|---|---|

| Screen Printing | Vibrant, durable, customizable | Small runs, curved surfaces |

| Hot Stamping | Luxurious metallic finish | Premium branding |

| Digital Printing | Flexible, cost-effective for short runs | Personalized, intricate designs |

| Offset Printing | High-quality, best for large quantities | Bulk production |

Tip: Use hot stamping or screen printing to create a premium look that attracts attention on the shelf.

Color

Color choices shape how customers feel about your product. Warm colors like red and orange create excitement and grab attention. Cool colors such as blue and green suggest calmness and trust. Neutral shades like black and white give a sense of sophistication. Brands like Nivea use blue to build trust, while others use bold colors to appeal to younger buyers. Consistent color use helps people recognize your brand and builds loyalty.

- Color is the most noticeable part of packaging.

- Over 60% of shoppers judge products by color alone.

- Bright colors catch the eye and influence buying decisions.

- Each color triggers a different emotion or message.

Note: Always consider cultural meanings of colors if you sell in different countries.

Caps

The cap style you choose affects both function and appearance. Flip-top caps allow one-handed use and quick access, perfect for lotions and gels. Pump caps give you controlled, hygienic dispensing for creams and thick products. Twist-open caps provide a secure seal and work well for toothpaste or ointments. Snap-on caps are lightweight and cost-effective, making them ideal for travel or single-use items. You can also customize caps with special finishes, colors, or logos to reinforce your brand identity.

| Cap Style | Functional Benefits | Typical Applications |

|---|---|---|

| Flip-Top | Easy, one-handed use; resealable | Lotions, gels, sunscreens |

| Pump | Controlled, hygienic dispensing | Creams, lotions, gels |

| Twist-Open | Secure seal; controlled dispensing | Toothpaste, ointments |

| Snap-On | Lightweight; quick application/removal | Travel, single-use products |

Choose a cap that matches your product’s texture and your customer’s needs for the best experience.

Practical Factors

Cost

You need to understand how different choices affect your packaging budget. Material selection, customization, and order size all play a role. Plastic tubes usually cost less than paper or bio-based options. Custom features like embossing, foil stamping, or special printing add to the price. Ordering more units lowers the cost per tube because fixed costs spread out over a larger batch.

| Cost Factor | Description | Impact on Budget |

|---|---|---|

| Material Choice | Plastic is generally less expensive than paper; sustainable or biodegradable materials cost more. | Material selection directly influences base cost. |

| Customization | Includes design complexity, printing, embossing, foil stamping, and inserts. Adds design and production time. | Increases overall packaging cost due to added features. |

| Economies of Scale | Higher volumes reduce per-unit fixed costs by spreading setup and tooling expenses over more units. | Larger orders lower unit cost but customization/material choices can still raise total budget. |

You can also save money by reducing package size or using stickers for branding. Foil stamping and tissue inserts add value at a low cost, especially when ordered in bulk.

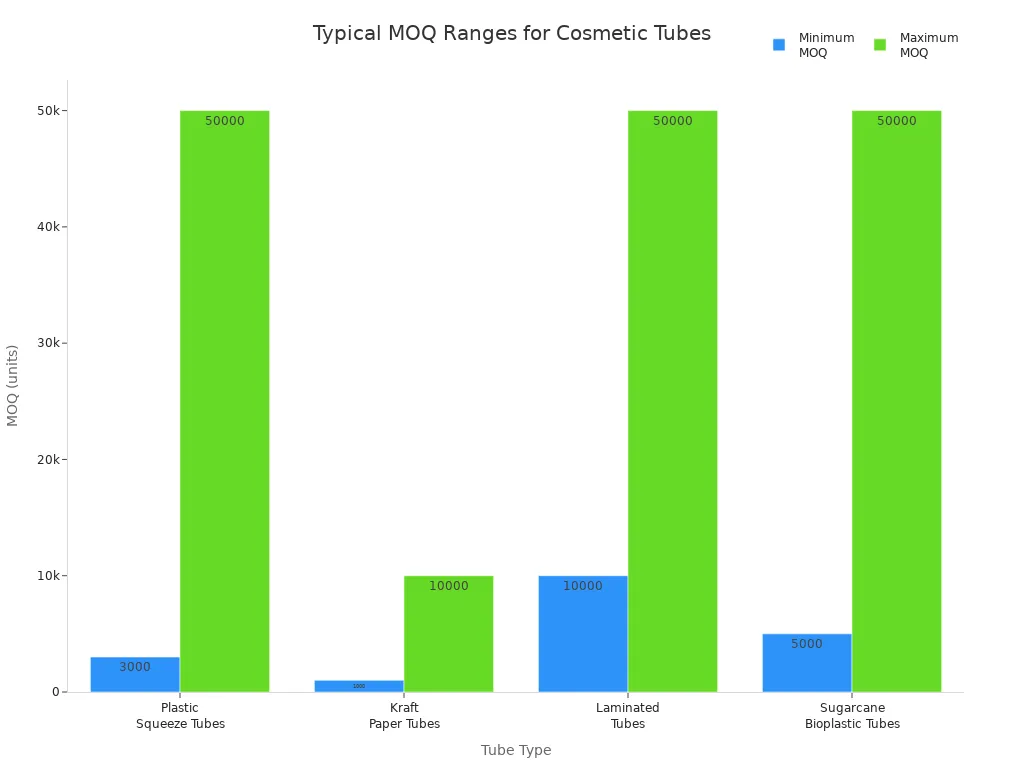

MOQ

Minimum order quantities (MOQs) set the smallest number of tubes you can buy from a supplier. Most suppliers require between 5,000 and 20,000 units per order. Standard tubes have lower MOQs, while custom designs need higher minimums. Planning your order size helps you manage costs and inventory.

| Tube Type | Typical MOQ Range (units) | Regions Mentioned | Notes on Customization and Factors Influencing MOQ |

|---|---|---|---|

| Plastic Squeeze Tubes | 3,000 – 50,000 | China, South Korea, U.S. | Lower MOQ for standard tubes; higher for custom designs. |

| Kraft Paper Tubes | 1,000 – 10,000 | China, Taiwan, U.S., Europe | Lower MOQ for basic; higher for custom printing and caps. |

| Laminated Tubes | 10,000 – 50,000 | China, India, Europe | MOQ increases with lamination layers and artwork. |

| Sugarcane Bioplastic Tubes | 5,000 – 50,000 | Brazil, China, South Korea | MOQ depends on customization and cap design. |

Supplier

Choosing a reliable supplier ensures you get safe, high-quality packaging. Xinfly Packaging stands out for its strong track record and wide range of options. You should evaluate suppliers using these steps:

- Check for cosmetic-grade materials and request safety certificates.

- Test pump quality and compatibility with your product by ordering samples.

- Review customization options and ask for prototypes.

- Look for sustainability credentials and environmental certifications.

- Confirm MOQs and pricing flexibility.

- Ask about lead times, shipping, and fulfillment support.

- Ensure responsive after-sales service for any issues.

Always compare samples from several suppliers before making a final decision.

Sustainability

Sustainability matters more than ever in packaging. You can choose from several eco-friendly options:

- Post-consumer recycled (PCR) plastic tubes reduce waste and support recycling.

- Aluminum tubes are endlessly recyclable and lightweight.

- Kraft paper tubes offer a biodegradable, natural look.

- Sugarcane bioplastic tubes use renewable resources and are carbon-neutral.

- Airless and mono-material tubes make recycling easier and protect your product.

- Lightweight designs cut shipping emissions and save resources.

Tip: Eco-friendly packaging not only helps the planet but also attracts customers who value sustainability.

Compare Suppliers

Research

When you compare suppliers, you want to make sure they can meet your needs and help your brand succeed. Start by looking at their manufacturing capabilities. A good supplier offers versatility and keeps up with new packaging trends. You should check if they use quality control procedures that go beyond industry standards. Strong customer service and a good reputation show that the supplier values your business.

Look for suppliers with years of experience. They know how to handle compliance and deliver on time. Design expertise is important, too. Some suppliers, like Xinfly Packaging, offer custom mold making and a wide range of products. You may want to choose a supplier who uses eco-friendly materials, such as PCR, paper, or bamboo. This helps your brand support sustainability.

Consider these factors when researching suppliers:

- Manufacturing versatility and innovation

- Strict quality control

- Reliable customer service

- Industry experience and compliance

- Custom design and mold making

- Use of sustainable materials

- Wide product range

- Practical features like easy filling, shipping durability, and good labeling space

- Sterilization facilities

- On-time delivery and fair pricing

- Help with export/import paperwork

Tip: Always check if the supplier meets national safety and environmental standards. This protects your brand and your customers.

Samples

Before you place a large order, ask for samples. Testing samples helps you see if the packaging fits your product and meets your quality standards. You should check how your formula interacts with the tube material. This step ensures the packaging does not harm your product’s stability, safety, or performance.

Sample evaluations include:

- Testing for leaks or cracks

- Checking how well the tube protects against air and moisture

- Making sure the packaging does not change your product’s color or smell

- Confirming the tube is easy to fill and use

These tests help you avoid problems after launch. They also show if the packaging meets regulations and keeps your customers safe.

Note: Sample testing is a key step. It helps you choose the best supplier and ensures your product stays safe and effective.

Choosing the right cosmetic tube involves more than just picking a container. You need to match tube features with your product’s needs and your brand’s personality. Packaging acts as your silent brand ambassador. Consider color, shape, and print methods to reflect your values and attract your audience. Focus on functionality, ease of use, and sustainability. Use this guide as a checklist, and reach out to trusted suppliers for samples and expert advice.

Choosing Cosmetic Tubes – Frequently Asked Questions

Materials, barrier, diameter/volume, orifice sizing, closures, finishes, sustainability, QA, MOQs, lead times and artwork—everything you need to specify the right tube with Xinfly Packaging.

1) Which tube material should I choose?

2) How do I match barrier level to my formula?

3) Round or oval—what’s better for my brand?

4) What diameter/volume should I pick?

5) How do I size the orifice for viscosity?

6) Which closures/applicators should I consider?

7) What finishes look premium on tubes?

8) Can cosmetic tubes be sustainable without losing aesthetics?

9) What QA tests should I require?

10) Are tubes e-commerce friendly?

11) Typical MOQs and lead times at Xinfly Packaging?

12) What artwork files do you need?

13) How do I keep colors consistent across reorders?

14) How should I compare quotes beyond unit price?

15) Why choose Xinfly Packaging?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.