How to Choose the Right Plastic Cosmetic Tube Manufacturer for Your Brand

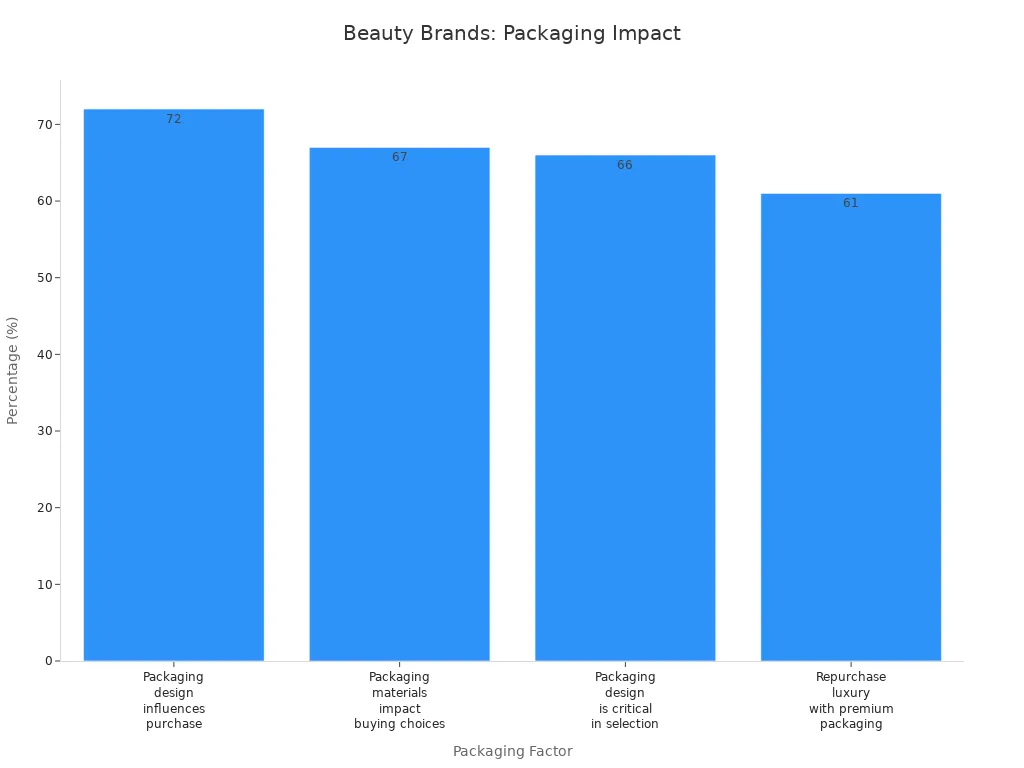

Packaging for cosmetics does more than just hold your product. It helps tell your brand’s story. Did you know most shoppers choose what to buy by looking at the packaging? In fact, 72% of shoppers decide based on the design.

When you choose plastic cosmetic tube manufacturers, you affect how people see your products. You also help your business grow. Good packaging can make your brand look better. It can also make customers want to buy again. Many brands now want eco-friendly options. So, picking a partner who cares about sustainability is important. Try not to make mistakes like choosing the wrong supplier. Make sure you talk clearly with your partner. Think about both the small details and the big plan. This will help your brand do well.

Key Takeaways

- Pick a cosmetic tube that fits your product’s formula. Make sure the material keeps out light, air, and water. This helps your product stay fresh.

- Use packaging to show off your brand. The design, color, and logo should share your brand’s story. These things help bring in customers.

- Think about the environment. Choose manufacturers who use eco-friendly materials and good practices. This will attract people who care about the planet.

- Check how good the manufacturer is and how much they can make. Find companies with good reviews and room to grow with your brand.

- Talk clearly with your manufacturer. Share what you need, ask questions, and ask for samples. This helps make sure you get what you want.

Product & Brand Needs

Cosmetic Tube Requirements

When you look for a cosmetic tube, think about your product. Your formula is important. Some ingredients do not work well with some plastics. You need a tube that keeps your product safe. The packaging should protect from light, air, and water. This helps your product last longer.

Here are some things to look for in cosmetic tubes:

- The tube material should work with your formula.

- You need a barrier to keep your product fresh.

- The packaging should match your brand’s style.

- You want good quality that is not too expensive.

- Caring for the planet is important.

You can pick plastic squeeze tubes, aluminum tubes, or laminated tubes. Each type has good and bad points. Plastic squeeze tubes cost less and are easy to design. But they do not block air or light well. Aluminum tubes protect your product better and are good for the planet. But they cost more money. Laminated tubes look nice and keep products safe. But it is hard to recycle them.

Branding & Customization

A cosmetic tube is more than a container. It is the first thing people see. The color, shape, and logo show your brand’s story. Good colors make your product look special. If your logo is easy to see, people trust your brand. The cap can help your logo stand out every time someone uses it.

Tip: Think of your packaging like a handshake. It is the first thing people notice.

You can design packaging for different products. You can pick special shapes, finishes, or printing styles. These choices help your brand look unique.

Sustainability Goals

Sustainability is very important for beauty brands. You want packaging that is better for the earth. Eco-friendly materials, like tubes made from recycled stuff, show you care. Many people want to buy products with green packaging. Ask your manufacturer about their green practices. Find out how they handle eco-friendly choices. This helps you reach your goals and connect with people who care about the planet.

Budget & Volume

You need to think about your money and how many tubes you need. If you buy a lot, you may pay less for each tube. If you buy only a few, each tube costs more. Talk to manufacturers about how many you need. See what fits your budget. Saving money is good, but do not forget about quality and caring for the planet. The best choice helps your brand grow and saves money.

Cosmetic Tube Material & Quality

Material Selection

Picking the right tube material is important for your brand. You want your packaging to look nice and protect your product. There are many types of cosmetic tubes. Each type has its own good points. Here are some common materials you will find in beauty products:

- Polyethylene (PE): Works well for daily skincare and cosmetics.

- Polypropylene (PP): Hard, recyclable, and handles oils and chemicals.

- Polyethylene Terephthalate (PET): Clear, light, and keeps out water and air.

- EVOH: Stops gas and smell, so your product lasts longer.

- Aluminum: Blocks light, air, and water. It is easy to recycle.

- Laminates (ABL & PBL): Good for large orders and protect well.

- Surlyn®: Looks fancy and does not scratch easily.

- Bioplastics (PLA, Sugarcane-based PE): Better for the earth.

- Acrylic (PMMA): Looks like glass and feels special.

Tip: Choose a material that fits your product and your brand.

Quality Standards

You want your tubes to be safe and high quality. This helps keep your customers happy. The cosmetic industry has strict rules for safety and looks. Here are some important rules and standards:

- ISO standards help companies follow world safety and quality rules.

- In the US, the FDA’s MoCRA sets rules for safety and labels.

- The EU uses Regulation (EC) No 1223/2009 for safety and labels.

- Australia uses AICIS for checking and labeling cosmetic products.

- ISO 22715 gives clear rules for packaging and labels.

Always ask your manufacturer if they follow these rules.

Safety & Durability

You want your tubes to last through shipping and use. Makers use sealing methods like heat sealing, ultrasonic sealing, and impulse sealing. These seals stop leaks and keep your product safe. Before tubes leave the factory, workers check them for quality. Tubes are packed well to stop damage. Some tubes can be locked or sealed for extra safety.

Note: Strong seals and tough packaging help your product arrive safe and ready.

Evaluating Plastic Cosmetic Tube Manufacturers

Reputation & Track Record

When you look for plastic cosmetic tube manufacturers, you want a partner you can trust. A good reputation means the company delivers on time and keeps quality high. You should check how long the manufacturer has been in business. Companies with many years of experience often know how to avoid problems. They also know how to keep your products safe and looking great.

Read reviews from other brands. Happy customers often share their stories. If you see many positive comments, you know the manufacturer cares about quality. Look for stories about on-time deliveries and products that meet expectations. You can also ask for references. Talking to other brands helps you learn about the manufacturer’s strengths and weaknesses.

Here are some things to check when you look at a manufacturer’s track record:

- Check if they have had any regulatory issues or violations.

- Look for ISO 9001 or GMP certifications. These show the company follows strict quality rules.

- See if they have ISO 14001 or BRC certifications. These show they care about the environment and safety.

- Ask about their quality control process. Good systems mean fewer mistakes.

- Make sure they have experience making high-quality cosmetic packaging.

- Test their product samples. This helps you see if the tubes meet your needs.

- Find out if they communicate well and answer your questions quickly.

You want a manufacturer who listens to you and helps you solve problems. Xinfly Packaging is a good example. Many brands trust them because they use high-quality materials and offer strong customization. They also have a global network and focus on eco-friendly options.

| Feature | Xinfly Packaging | Other Manufacturers |

|---|---|---|

| High-quality materials | Yes | Varies |

| Customization capabilities | Yes | Limited |

| Global distribution network | Yes | Varies |

| Reputation among brands | Strong | Varies |

| Focus on eco-friendly options | Yes | Limited |

Production Capacity

You need to know if plastic cosmetic tube manufacturers can keep up with your orders. If your brand grows, you want your supplier to grow with you. Some top manufacturers can make over 600 million tubes each year. That means they can handle big orders and help you scale up when you need to.

Ask about their production lines. Can they make enough tubes for your launch? Will they be able to help if you get a big order from a new store? You want a partner who can say yes to both. If you plan to test new products, check if they can handle small runs too. This helps you control cost and avoid waste.

Here are some things to ask about production capacity:

- How many tubes can they make each month?

- Can they handle both small and large orders?

- Do they have the right machines for your tube style?

- How do they keep quality high when making lots of tubes?

- Can they scale up if your brand gets more popular?

If a manufacturer cannot meet your needs, you may face delays or run out of stock. This can hurt your brand and cost you sales. Always choose a partner who can grow with you and keep your cost under control.

Delivery & Flexibility

Fast and reliable delivery is key. You want your tubes to arrive on time so you can launch your products without stress. Top plastic cosmetic tube manufacturers can deliver samples in about 10 working days after you approve the artwork. Full production usually takes 30 to 35 days. Some can deliver even faster, in as little as 10 days for urgent orders.

Flexibility matters too. Your brand may need to change order sizes as you grow. Good manufacturers act like part of your team. They help you adjust production up or down based on demand. This keeps your cost low and helps you avoid extra stock.

Here’s what flexible manufacturers can do for you:

- Adjust production levels quickly if your sales go up or down.

- Help you test new products without big commitments.

- Support you if you need to change your order at the last minute.

- Keep quality high, even when making changes.

- Respond fast to market trends and customer needs.

A flexible partner helps you save cost and stay ahead of the competition. They make it easy to try new ideas and grow your brand. When you choose plastic cosmetic tube manufacturers who deliver on time and adapt to your needs, you set your business up for success.

Tip: Always ask about lead times and how the manufacturer handles rush orders. This helps you plan better and avoid extra cost.

Customization & Support

Design Options

You want your cosmetic tubes to look different from others. Customization helps your product get noticed. Many beauty brands like special finishes and effects. These make their packaging stand out. Here are some popular choices:

| Customization Option | Description |

|---|---|

| Foil Stamping | Adds a shiny, metallic look to the tube. This makes it more eye-catching. |

| Embossing | Makes a raised design on the tube. This adds texture and a fancy feel. |

| Matt Finishes | Gives the tube a flat, non-shiny surface. This makes it look classy. |

You can use more than one of these features together. This helps you make a design that sells well. When you work with a manufacturer, you get help from packaging designers. They help you pick the best look for your brand. You can choose colors, shapes, and printing styles you like. This way, your product stands out in a busy market.

Communication & Service

Good communication makes everything easier. You want a manufacturer who listens to your ideas. They should answer your questions quickly. Many companies have a special design studio. You get to work with experts who know what is popular. They help you from your first idea to the finished product.

Manufacturers often give custom packaging that fits your needs. They look at your company size and your goals. You get advice on what works best for your brand. This support helps you avoid mistakes and saves time.

Tip: Always ask if you can talk to the design team. This helps you get the results you want.

Sampling & Prototyping

Before you buy lots of tubes, you want to see a sample. Most top manufacturers offer quick samples and prototypes. Here is how some companies do this step:

| Manufacturer | Sampling Process | Prototyping Details |

|---|---|---|

| Seme Packaging | Gives 3D pictures and tests samples before making the tubes. | Samples are checked for how they work and how strong they are. |

| A Love Y | Offers fast samples so you can check and change designs. | Makes it easy to launch new products and keep costs low. |

| Othilapak | Gives free design help and quick samples in 3 days. | Prototype molds and real samples are ready in 15 days for you to see. |

You can see and feel your tube before you order a lot. This step helps you find problems early and fix them. Fast samples mean you can launch new products quickly and feel sure about your choice.

Choosing the Right Cosmetic Tube

Comparing Quotes

When you start looking for the right cosmetic tube, you will get quotes from different manufacturers. It is smart to compare these quotes carefully. Do not just look at the price. You want to see what you get for your money. Here are some things to check:

- Cost: Plastic squeeze tubes usually cost less. They work well for big orders.

- Material Properties: Aluminum tubes protect your product better and look more premium. Laminated tubes give you a mix of protection and good price.

- Environmental Impact: Aluminum tubes are easy to recycle. This helps if your brand cares about the planet.

- Design Flexibility: Plastic tubes let you try many shapes and styles. They are strong and work for lots of designs.

Tip: Ask each manufacturer what is included in their quote. Some may offer extra services or faster delivery.

References & Samples

You want to feel sure about your choice before you order the right cosmetic tube. Ask for references and samples from each manufacturer. References show you if other brands trust this company. Samples let you see and touch the tubes before you buy a lot.

Try the samples in different ways:

- Look at the tube under different lights.

- Compare it with other brands for feel, look, and scent.

- Test it on different skin types.

- Use it for a few days to see how it holds up.

- Ask friends or coworkers what they think.

Testing samples helps you find the right cosmetic tube that fits your brand and keeps your customers happy.

Final Decision

Now you are ready to pick the right cosmetic tube for your brand. Follow these steps to make your final choice:

- Choose the tube type and size that fits your product.

- Work with the manufacturer to make a 3D digital prototype.

- Ask for a real sample to check quality.

- Approve the sample and start mass production.

You should also match the tube material to your formula. Pick tubes made from one material if you want easy recycling. Try using recycled or bio-based materials to lower your carbon footprint. Design your tube so it is easy to recycle. Give clear instructions to your customers about how to recycle the packaging.

Remember: Picking the right cosmetic tube is not just about looks. It is about quality, safety, and making your brand stand out.

Picking the right cosmetic tube manufacturer is very important for your brand. If you choose a partner that fits your needs, you will do well. Take your time and ask lots of questions. Try to build a good relationship with your supplier. This way, you can get better prices and help your products grow. Use this checklist when you look for a new supplier:

- Check how hard it is to squeeze the tube and if the seal is strong

- Try the tubes with real people to see how they work

- Make sure your logo and colors look correct on the tube

- Ask if they have ISO 9001 certification and do quality checks

- Pick the right materials and closures for your product

- Choose eco-friendly options if you can

If you think carefully, you will get better partners and products. Follow these steps each time you pick a manufacturer.

Choosing a Plastic Cosmetic Tube Manufacturer – FAQs

Key factors to evaluate: materials & barrier capability, printing quality, QA system, sustainability, MOQs & lead times, pricing, documentation and global shipping support.

1) What capabilities should a plastic tube manufacturer have?

2) Which materials should they offer?

3) How do I match barrier performance to my formula?

4) What printing and finish options indicate premium quality?

5) How do I evaluate their quality system?

6) What is a reasonable MOQ and lead time?

7) How should I brief manufacturers for apples-to-apples quotes?

8) What are the main cost drivers—and how to control them?

9) Which sustainability options should be available?

10) What documents and certifications should I request?

11) How do logistics and Incoterms affect total landed cost?

12) What service standards should I expect post-order?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.