How to Get the Best Results with 50ml Cosmetic Tube Printing

Want your 50ml cosmetic tube packaging to stand out? You need to make sure every detail matches your brand. Start with a printing method that shows off your brand colors. Choose artwork that fits your brand style. Pick materials that support your brand message. Work with a supplier who understands your brand needs. If you focus on each step, your brand will shine every time.

- Tip: Always share your brand guidelines with your supplier.

Key Takeaways

- Pick the best printing way for your cosmetic tubes. This helps your design look good and last longer.

- Use vector files like PDF or AI. These make your artwork sharp and clear on the tubes.

- Choose materials that match your brand message. This makes your product look better.

- Always ask for samples and proofs first. This helps you check the quality before making many tubes.

- Talk clearly with your supplier. This helps you avoid mistakes and get great results.

Printing Methods

Picking the right printing method is important. It helps your 50ml cosmetic tube look good and last long. Each method has its own benefits. Let’s look at the main choices so you can decide what works best.

Silk Screen

Silk screen printing makes colors look bright and bold. The ink is thick, so designs stand out. This method is good for simple graphics and solid colors. If you want your logo to be noticed, silk screen printing is a great pick. It is strong, so tubes stay nice even after lots of use.

| Printing Method | Advantages |

|---|---|

| Screen Printing | Makes colors bright and solid, good for big orders. |

| Digital Printing | Shows small details and colors well, good for small orders and custom designs. |

Silk screen printing lets you pick many colors and finishes. If you need many tubes with the same look, this way saves money.

Offset

Offset printing is good for detailed designs. You get smooth color changes and sharp pictures. This method is best for art with many colors and tiny details. Offset printing is great for brands that want a fancy look.

- Offset printing gives high detail and smooth color changes.

- It is good for hard patterns and photo-like images.

Offset printing uses more power and makes more waste than other ways. If you care about the planet, you may want to try something else.

Digital

Digital printing is flexible. You can change designs fast and print small amounts without big setup costs. This way is good for special or seasonal packaging. You get clear details and true colors, so your art looks right.

- Digital printing lets you change and customize designs quickly.

- It is good for small orders, which means less waste.

- Digital printing is better for the earth, with a smaller carbon footprint.

If you want to try new designs or make special tubes, digital printing is a smart choice.

Hot Stamping

Hot stamping makes your tubes look fancy. You get shiny gold or silver that catches the eye. This way is best for logos or special parts. Hot stamping costs more and has fewer color choices, but it looks high-end.

| Feature | Hot Stamping | Silk Screen Printing |

|---|---|---|

| Setup Cost | High | Low |

| Per Unit Cost | Expensive | Cheaper |

| Color Range | Few (gold, silver) | Many |

| Best for | Fancy branding | Bright, bold designs |

| Durability | Medium | High |

Hot stamping does not break down in nature and can add to trash if not removed before recycling. If you care about the earth, think about this before picking hot stamping.

Flexographic

Flexographic printing uses bendy plates and quick-drying inks. It gives good quality fast, so it is good for big orders. Flexographic printing uses safer inks, so it makes less pollution and waste.

| Printing Technique | Environmental Impact |

|---|---|

| Flexographic | Uses safer inks, makes less air pollution, and less waste. |

| Offset | Uses lots of energy, makes more waste, and uses bad chemicals. |

Flexographic printing works with many tube types. You get steady results and lower prices for big jobs. If you want good quality, speed, and care about the earth, flexographic printing is a good pick.

Matching Method to Material and Design

You need to match the printing method to your tube and design. Some inks work better on plastic, others on paper or laminate. If your design has tiny details, offset or digital printing works best. For bright colors, silk screen printing is best.

- Silk screen printing gives bright colors and lasts long, good for bold designs.

- Offset printing is best for hard designs with high detail and smooth color changes.

- Hot stamping adds a shiny finish, making tubes look fancy.

- Digital printing lets you change designs fast, good for small orders.

Gravure printing is strong. It uses inside printing, so the ink is safe from damage. Your design stays nice for a long time, which is good for products that need strong packaging.

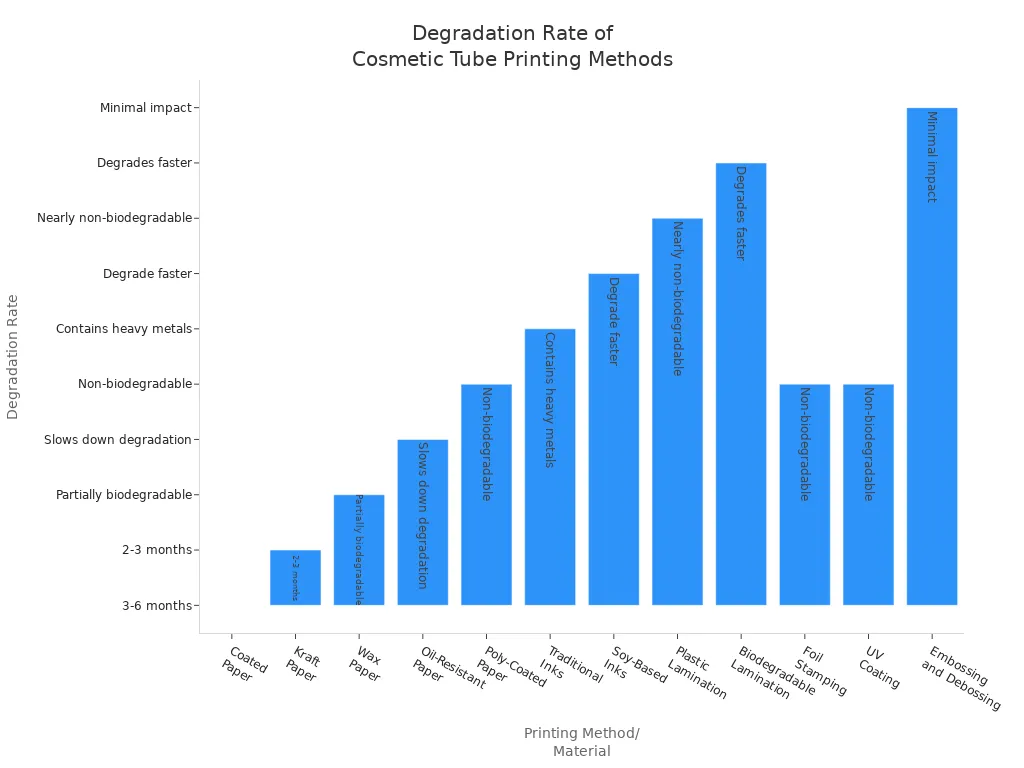

If you care about the planet, check how each way affects the earth. Digital printing makes less waste and has a smaller carbon footprint. Flexographic printing uses safer inks and makes less pollution. Offset printing uses more energy and chemicals, so it is not as green.

Tip: Always ask your supplier about ways to customize and how each printing method works with your tube and design. This helps you avoid problems and get the best results.

Artwork Prep

Getting your artwork ready is a big step in making your 50ml cosmetic tube look amazing. If you want your design to print sharp and true to your brand, you need to follow a few key steps. Let’s break down what you need to know.

File Formats

You want your design to look crisp and clear on every tube. The best way to do this is by using the right file formats. Most suppliers ask for vector files because they keep your artwork sharp, no matter the size. Here are the top choices:

- PDF (Portable Document Format)

- AI (Adobe Illustrator)

- EPS (Encapsulated PostScript)

These formats work well because they are vector-based. You can resize your logo or graphics, and they will never get blurry. Vector files also make it easy to separate colors for printing. Always create your artwork in a vector program like Adobe Illustrator. This way, your design stays perfect from your computer to the finished tube.

Tip: Set your artwork resolution to at least 300 dpi. This gives you high-quality prints with no fuzzy edges.

Color Management

Color is a big part of your brand. You want your tubes to match your brand colors every time. Good color management helps you do that. If you use the right color settings, your tubes will look the same in every batch.

| Key Aspect | Explanation |

|---|---|

| Color Accuracy | Makes sure your printed tubes match your brand colors. |

| Consistency | Keeps colors the same across different print runs. |

| Brand Perception | High-quality color makes your brand look professional and trustworthy. |

| Ink Density Management | Stops colors from looking faded or smudged. |

You should always use the same color profiles in your files. If you use Pantone or CMYK codes, share them with your supplier. This helps everyone stay on the same page. When your colors stay true, your brand stands out and looks reliable.

Note: Ask your supplier for a printed proof before you start a big order. This way, you can check the colors and make changes if needed.

Placement and Bleed

Placement and bleed are easy to overlook, but they make a huge difference in the final product. You want your design to fit the tube just right, with no surprises.

- Placement: Make sure your logo, text, and images sit exactly where you want them. Use a template from your supplier to line everything up. Double-check that nothing important sits too close to the edge.

- Bleed: Bleed is extra space around your design. It lets the color or image go past the edge of the tube. This way, when the tube gets trimmed, you don’t end up with white lines or gaps.

Bleed matters for three big reasons:

- Accuracy and Precision: Bleed covers small shifts during cutting, so your design always looks seamless.

- Professional Appearance: It keeps your tubes looking polished, not sloppy.

- Consistency Across Print Jobs: Bleed helps every tube look the same, even in big orders.

Pro Tip: Always add bleed to your artwork—usually about 2-3 mm. Check with your supplier for their exact requirements.

If you follow these steps, your artwork will print just the way you want. You get sharp images, true colors, and a professional finish every time.

50ml Cosmetic Tube Packaging:

Material Compatibility

When you choose a cosmetic tube material, you set the stage for how your design will look and last. Plastic tubes feel light and flexible. They work well for everyday products and let you print bright colors with silk screen or offset methods. Aluminum tubes give your 50ml cosmetic tube packaging a luxury vibe. They block out air and light, keeping your product fresh. Laminated tubes mix the best of both worlds. You get strong barrier protection and a smooth surface for printing. These tubes help your product last longer and keep active ingredients safe.

Here’s a quick look at how printing methods work with different materials:

| Printing Method | Description |

|---|---|

| Offset Printing | Prints up to 8 colors. You can pick glossy, semi-matt, or matt finishes. |

| Silk Screening | Works on many surfaces. Makes sharp images and costs less. |

| Hot Stamping | Adds metallic foil that sticks well and looks fancy. |

| Flexographic Printing | Gives fine detail and clear images. Great for photo-like designs. |

Laminated tubes stand out in 50ml cosmetic tube packaging. They block oxygen, moisture, and light. Your product stays fresh two to three times longer. You also get a better surface for printing, so your design pops.

Tip: Always ask your supplier which printing method matches your cosmetic tube material. This helps you avoid smudges or faded colors.

Finish Impact

The finish you pick changes how people see your 50ml cosmetic tube packaging. Matte finishes feel soft and look classy. They cut down glare and hide fingerprints. Glossy finishes shine and make colors look bold. Your tube looks polished and grabs attention. Metallic finishes add sparkle and make your packaging stand out on the shelf.

- Matte finish gives a smooth, velvety look. It lasts longer and keeps your tube looking clean.

- Glossy finish makes colors pop. Your tube looks high-end and fresh.

- Metallic finish adds shine. People notice your product right away.

Plastic tubes often look simple and cost less. Aluminum tubes feel fancy and protect your product better. Laminated tubes let you print full-color designs and stay flexible. You get a premium look without spending too much.

Note: The finish you choose can change how customers feel about your brand. Matte feels calm and modern. Glossy feels lively and rich. Metallic feels special and exclusive.

If you want your 50ml cosmetic tube packaging to match your brand, think about both the material and the finish. You get better print quality, longer shelf life, and a look that fits your style.

Printing and Labeling: Common Mistakes

Mistakes can happen if you do not pay attention. You want your 50ml cosmetic tube to look great. Let’s talk about some common mistakes and how to stop them.

Design Errors

Design problems can start before printing begins. If you use bad materials or make a design too busy, your tube may look messy. Labels that are hard to read or missing can confuse people. This can even cause safety problems. If your packaging does not match your brand, people may not trust your product.

| Error Type | Explanation |

|---|---|

| Poor Materials | Bad packaging hurts your product and your brand’s name. |

| Overly Complicated Design | Busy designs look messy and turn buyers away. |

| Ill-defined Labels | Hard-to-read or missing labels can cause safety problems. |

| Ignoring Brand Identity | Packaging that does not fit your brand confuses customers. |

Tip: Keep your design simple and clear. Make sure your labels are easy to read and match your brand’s style.

Production Issues

Production problems can ruin a good design. You might see tiny lines, cracks, or rough spots on your tubes. Sometimes, tubes get dents or scratches during shipping. Problems like stains, bends, or painting mistakes can make your packaging look cheap.

- Tiny lines can show up after polishing.

- Tube defects happen when the temperature is wrong.

- Welding problems make rough spots and weak tubes.

- Cracks can form if machines run too fast.

- Black and white lines come from uneven heating.

- Marks, stains, and oil spots appear during cutting.

- Twists, bends, and scratches often come from bad handling.

- Dents can happen during transport.

- Painting mistakes like dust, bubbles, or overlap ruin the finish.

Note: Check your tubes often during production. This helps you find problems early and keep your tubes looking good.

Quality Control

Quality control keeps your tubes safe and looking nice. You should test your materials and check if they are eco-friendly. Watch the tube-making process to avoid problems. Use high-quality printing for bright colors and sharp images. Test labels to make sure they stick and do not fade. Always check barcodes and labels for accuracy.

| Quality Control Measure | Description |

|---|---|

| Inspection of Raw Materials | Test materials for safety and rules. |

| Sustainability Checks | Make sure materials are good for the earth. |

| Extrusion and Forming | Watch tube strength and size. |

| High-Resolution Printing | Use good tech for bright designs. |

| Adhesion Tests | Make sure labels stay on and do not fade. |

| Barcode and Regulatory Labeling | Check placement and rules. |

| Drop, Pressure, Leakage Tests | Test tubes for strength and leaks. |

| Heat, Cold, UV Resistance | Make sure tubes last in tough conditions. |

Ask your supplier about their quality checks. Look at shipments when they arrive and store your labels safely. If your supplier checks often and helps you, you save money and make fewer mistakes.

Pro Tip: Always test samples before making a big order. This step saves you time and money.

Supplier Collaboration

Communication

You want your cosmetic tubes to look just right. Talking clearly with your supplier helps a lot. First, share your design ideas and brand rules. Tell your supplier which printing method you like best. Different methods work for different looks:

- Silk screen printing is good for bold logos and solid colors.

- Offset printing gives smooth finishes for detailed designs.

- Hot stamping adds shiny metal for a fancy look.

- Heat transfer printing lets you use full-color pictures with sharp lines.

- Digital printing is great for small orders and custom tubes.

Ask about eco-friendly packaging and different finishes. If you explain what you want, your supplier can help you choose. Good talking helps you avoid mistakes and keeps your project moving.

Tip: Write down what you need and send pictures. This helps your supplier see what you want.

Samples & Proofs

Always ask for samples and proofs before making lots of tubes. Samples let you touch the tube and check how it feels. Proofs show how your design will look on the tube. You can see the colors, finish, and where things are placed. If something is wrong, you can ask for changes. This step saves money and stops big mistakes. You get a final tube that matches what you approved.

Note: Samples help you find problems early. You can check if the tube uses eco-friendly materials and fits your brand.

Xinfly Packaging

Working with a skilled supplier like Xinfly Packaging has many good points. You get tubes that keep your product safe with tight seals. The tubes let you use your product without mess. Xinfly offers green packaging that attracts people who care about the earth. You can pick special sizes and shapes to make your brand stand out. Xinfly follows new trends and uses earth-friendly materials. In 2022, cosmetic tubes were 8% of the world’s cosmetic packaging market. This shows how important good packaging is for your brand.

If you want good results, work with a supplier who knows the business. Xinfly Packaging helps you make tubes that look nice and work well.

You want your cosmetics to stand out. Start with a smart printing method and prepare your artwork with care. Pick materials that match your brand and test samples before mass production. Work with trusted suppliers for packaging to make your product shine. Follow these steps:

- Talk with your supplier about your brand and needs.

- Check samples for color, sealing, and design.

- Inspect every batch for quality.

Unique packaging helps your cosmetics tell your brand’s story. Strong partnerships lead to exciting launches and boost your brand’s reputation.

50ml Tube Printing – Frequently Asked Questions

Dial in standout results on 50ml tubes: print method selection, artwork setup, colour control, registration, finishes, durability, compliance, MOQ/lead time and cost control.

1) Which printing method is best for 50ml tubes?

2) What base materials print most cleanly?

3) How should I prepare artwork for a 50ml tube?

4) How do we control colour accuracy?

5) What about registration and wrap alignment on small tubes?

6) How do we avoid gradient banding and small text fill-in?

7) Which primers/varnishes improve adhesion and look?

8) What finishing effects work well on 50ml formats?

9) How do we test durability for e-commerce and travel?

10) Any compliance or safety considerations for inks?

11) What are typical MOQs and lead times for printed 50ml tubes?

12) How can I control cost without sacrificing quality?

13) What specs should I send to get an accurate print quote?

14) Any special tips unique to 50ml size?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.