How to Reduce the Procurement Cost of Cosmetic tube-Find a right Cosmetic tube supplier

Reducing the procurement cost of cosmetic tube is a crucial consideration for many cosmetics companies while maintaining product quality and brand image. Find a right Cosmetic Tube Supplier. The following strategies can effectively reduce the procurement cost of cosmetic tube:

Key Takeaways

- Reducing the procurement cost of cosmetic tube is vital for cosmetics companies to maintain quality and brand image.

- Implement strategies like selective raw material sourcing, scaled procurement, and optimized design to cut costs.

- Find a reliable cosmetic tube supplier who offers a balance of quality and competitive pricing.

- Utilize logistics management and improve inventory practices to further reduce procurement costs.

- Consider innovative technologies and regular supplier evaluations to ensure cost-efficiency.

1. Selective Raw Material Sourcing

Cosmetic tube is typically made of materials such as plastic (such as PE, PP) or aluminum. By collaborating with suppliers to selectively source cost-effective raw materials, costs can be reduced while ensuring product quality.

- Optimizing Material Selection: For example, choosing high-performance yet relatively low-cost plastics, or reducing thickness without compromising packaging quality.

- Centralized Procurement: Establishing long-term cooperation agreements with suppliers and centralizing material procurement can result in more favorable pricing.

2. Scaled Procurement

- Increased Procurement Volume: For stable demand, centralized procurement of cosmetic tube can yield volume discounts and reduce the cost of each tube.

- Procurement Plan Management: Rationally plan procurement cycles to avoid rush orders and temporary needs, thereby reducing the risk of overpriced purchases.

3. Optimize Design

- Cosmotic tube design, including size, shape, and material usage, impacts production costs. Design optimization can reduce unnecessary costs.

- Standardized Design: Adopt industry-standard tube sizes and designs to avoid the high costs associated with customized designs.

- Reduce Complex Processes: Avoid overly complex processes like printing and coating, opting for simple yet efficient production processes.

4. Find the Right Cosmetic Tubes Supplier

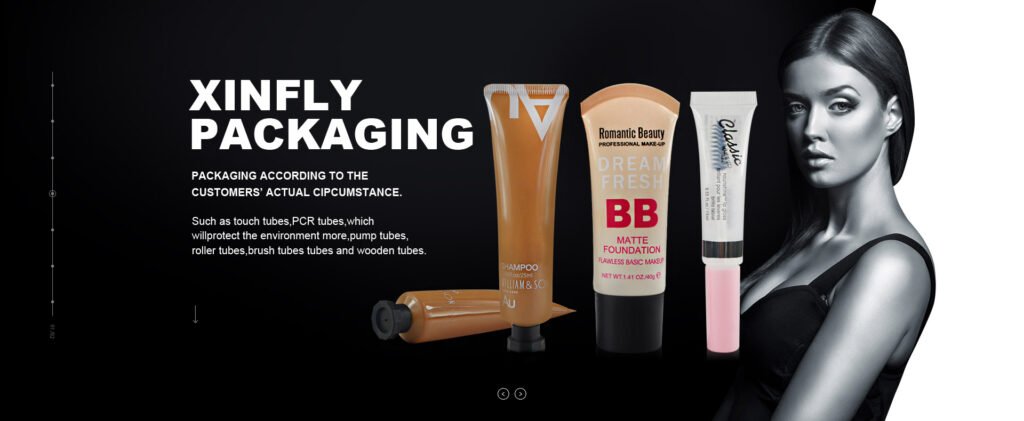

Choosing a reliable tube manufacturer and supplier is crucial. The right supplier will not only provide high-quality products, but also offer competitive pricing and flexible partnerships.Such as Xinfly Packaging. Jiangsu Xinfly Packaging Co.,Ltd, are a professional factory producing cosmetic tubes with more than 20 years of production experience.

- Global Sourcing: Large cosmetics brands can consider global sourcing to find suppliers with more competitive pricing, especially in regions with low labor costs (such as Southeast Asia or mainland China).

- Balance Between Quality and Price: While price is important, quality should not be sacrificed. Ensure that the supplier you choose offers a balanced solution in terms of both price and quality.

5. Utilize Packaging Outsourcing Services

- Outsourced Production: Some cosmetics companies choose to outsource the production of tubes to professional packaging companies. This reduces the cost of building their own production lines and often offers more customized services.

- Increase Partnership Models: By establishing long-term partnerships with outsourcing companies, you can enjoy more favorable prices and more stable supply.

6. Improve Logistics Management

- Optimize Transportation Solutions: Reduce logistics costs by rationally arranging transportation routes and selecting appropriate transportation methods (such as ocean freight, bulk shipping, etc.). Logistics costs can be a significant portion of the total cost, especially for tubes sourced internationally.

- Reduce Packaging Volume: While ensuring the tubes are not damaged, reducing unnecessary space during transportation can reduce transportation and storage costs.

7. Improve Inventory Management

- Reduce Inventory Costs: As a critical material in the production process, accurate inventory management can effectively prevent capital tie-ups caused by overstocking.

- On-demand procurement: Accurately forecast market demand to avoid blindly over-purchasing tubes and reduce waste.

8. Alternative Materials and Innovative Technologies

In recent years, with technological advancements, a growing number of new, environmentally friendly, and cost-effective tube materials have emerged on the market. For example, the use of biodegradable plastics or new composite materials is not only environmentally friendly but also potentially cost-effective.

- Green Cosmetic Packaging: Consumers are increasingly concerned about environmental issues. Using environmentally friendly materials not only reduces procurement costs but also enhances brand image and market competitiveness.

- Automated Production: Introducing advanced production lines and automated equipment can improve production efficiency, reduce labor costs, and enhance production consistency and precision, further reducing costs.

9. Regular Evaluation and Negotiation with Suppliers

- Regular Evaluation of Cosmetic Tube Supplier Performance: Regularly evaluate existing suppliers for factors such as product quality, delivery time, and price. If a supplier fails to offer competitive pricing or meet delivery time requirements, consider switching suppliers.

- Proactive Price Negotiation: Maintaining good communication and negotiation with suppliers can not only secure better pricing, but also secure longer payment terms or better after-sales service.

Summary:

Reducing the procurement cost of cosmetic tubes requires a multi-faceted approach, encompassing everything from raw material sourcing, supplier selection, production process optimization, and logistics management. By flexibly applying these strategies, you can reduce costs while ensuring product quality and brand image are not compromised. For cosmetics companies, cost control isn’t just about choosing a price; it’s a comprehensive optimization process across the entire process.

Reducing Cosmetic tubes Procurement Costs: Frequently Asked Questions (FAQs)

1. How to Choose the Right Cosmetic tubes Supplier?

- Key Factors in Supplier Selection: Quality Assurance, Reasonable Pricing, Delivery Time, Production Capacity, and After-sales Service. First, evaluate the supplier’s production standards and whether they can provide quality assurance that meets your requirements.

- Partnership Model: Consider long-term partnerships, negotiate volume discounts, and establish a stable cooperative relationship.

2. How do the raw materials for cosmetic tubes affect procurement costs?

- Different raw materials (such as PE, PP, and aluminum) have a direct impact on costs. For example, aluminum tubes are generally more expensive than plastic tubes, but they are popular in certain high-end products for their unique texture.

- Raw Material Optimization: Selecting the right materials and reaching purchasing agreements with suppliers can save costs. For example, purchasing cheaper plastic raw materials in bulk can be done.

3. How can I reduce procurement costs by optimizing tube design?

- Standardized Design: Using standardized sizes and shapes to avoid special customization can reduce production and mold development costs.

- Simplified Process: Reducing complex processes such as printing, hot stamping, or special coatings can eliminate unnecessary production steps and reduce unit costs.

4. Does Bulk Purchasing Reduce Costs?

- Bulk Purchasing Reduces Costs: Bulk purchases often offer bulk discounts from suppliers. In addition, customers who purchase in large quantities are more likely to receive priority production and delivery arrangements.

- Inventory Management: Be careful to avoid over-purchasing, which can lead to inventory backlogs and increase capital and storage costs.

5. How to Optimize Logistics Costs?

- Transportation Method Selection: Choose the most appropriate transportation method based on order volume and delivery time. For example, sea freight is suitable for large orders, while air freight is suitable for urgent orders.

- Reducing Packaging Space Waste: While ensuring transportation safety, minimize the volume of tube packaging to improve transportation efficiency and reduce transportation costs.

6. How to Reduce tube Procurement Costs by Outsourcing Production?

- Advantages of Outsourcing: Partnering with a professional packaging company can result in lower production costs, especially for small companies that don’t need to invest in large-scale production lines.

- Considerations for Selecting an Outsourcer: Ensure the outsourcer has sufficient production capacity and quality control capabilities to ensure delivery and quality standards.

7. Does Green Cosmetic Packaging Affect Procurement Costs?

- Short-Term Costs: Green materials (such as biodegradable plastics) may be slightly more expensive, but through branding and marketing, they can increase consumer loyalty and market share, thereby boosting long-term profits. * **Environmental Policy Support**: Some countries and regions offer tax incentives or policy support to companies using environmentally friendly materials, which can help reduce overall costs in the long term.

8. How can I manage cosmetic tube inventory to reduce costs?

- Accurate Demand Forecasting: Through data analysis and market forecasts, plan tube purchase quantities in advance to avoid excessive inventory backlogs.

- Implementing Just-in-Time (JIT) Strategies: Adopting just-in-time production and purchasing ensures optimal inventory levels, reducing inventory holdings and storage costs.

9. Is it necessary to regularly evaluate cosmetic tube supplier performance?

Regular evaluations are necessary: Regularly evaluate suppliers’ pricing, delivery on-time performance, product quality, and service. If a more competitive supplier is identified, consider switching to a different supplier to obtain better pricing and service.

10. How can automated production help reduce cosmetic tube cost?

- Improving Production Efficiency: Automated production lines can significantly increase production speed and accuracy, reduce labor costs, and lower error rates.

- Reducing the defect rate: Automated control ensures that every batch produced meets standards, avoiding the additional costs associated with quality issues.

By combining the above strategies, cosmetics companies can effectively reduce procurement costs while ensuring tube quality and brand image. From optimizing raw material sourcing, bulk purchasing, and cosmetic tube design improvements to rationally planning cosmetic tube supplier management, optimizing logistics, and outsourcing, all these factors can contribute positively to cost control.

Reduce Cosmetic Tube Procurement Cost – Frequently Asked Questions

Practical tips to cut total landed cost and pick a reliable supplier: materials, print stack, molds, MOQ, forecasting, QC, logistics, and contract terms.

1) What drives the unit cost of cosmetic tubes the most?

2) How can I reduce cost without hurting quality?

3) Does choosing standard molds really save money?

4) How many printing methods should I combine?

5) What MOQ strategy lowers the landed cost?

6) How do Incoterms and logistics affect total cost?

7) What supplier qualifications should I check?

8) How to avoid hidden costs from defects and delays?

9) Can PCR or wheat-straw options still be cost-effective?

10) Which contract terms help control cost risk?

11) How should I plan sampling and lead time?

12) Any quick wins for first orders with a new supplier?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.