Laminate Tubes Simple Steps to Smarter Sourcing

When you start looking for laminate tubes, you should think about some important things. These are material choice, tube size, printing needs, order amount, supplier location, quality, customization, cost, and compliance. Each thing changes how the tube packaging works, how much you pay, and how fast you get your products.

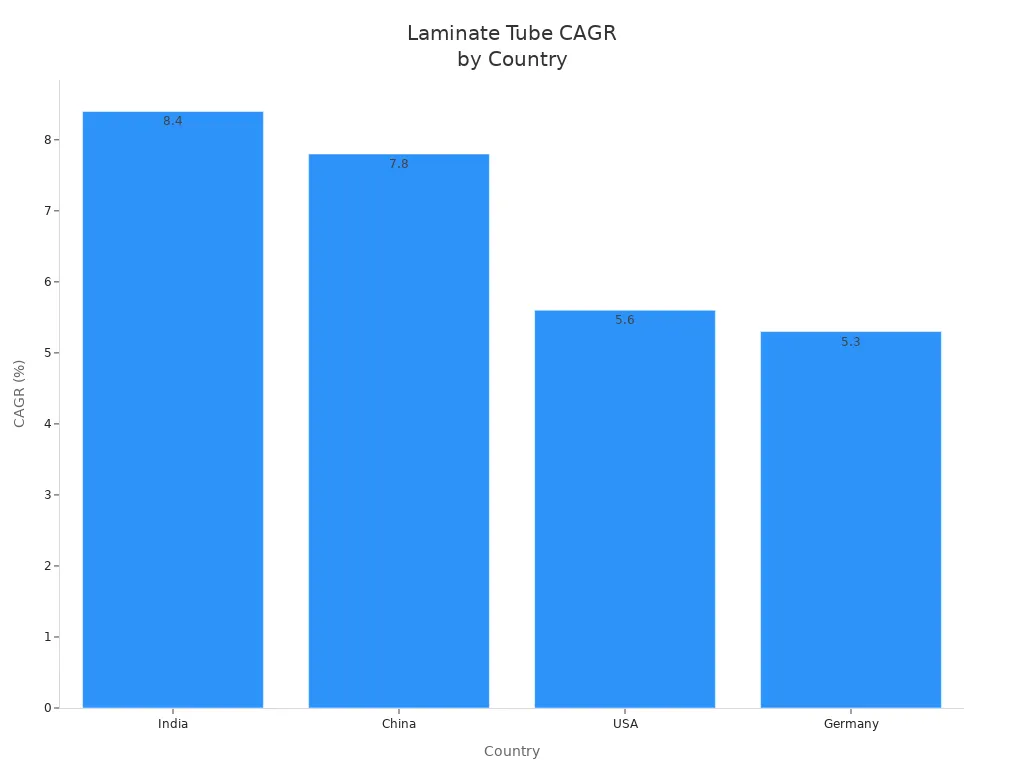

| Metric | Value |

|---|---|

| Industry Size (2025) | USD 2.8 billion |

| Forecast (2035) | USD 5.2 billion |

| CAGR (2025 to 2035) | 6.4% |

| Dominant Tube Capacity | 50-100ml (38.2% share) |

| Growth in India (CAGR) | 8.4% |

| Growth in China (CAGR) | 7.8% |

| Growth in USA (CAGR) | 5.6% |

| Growth in Germany (CAGR) | 5.3% |

You can make smarter choices for tube packaging if you look at trends like using eco-friendly materials, better barrier features, and new design ideas. These things help you avoid mistakes and make your process for getting laminate tubes better.

Key Takeaways

- When sourcing laminate tubes, consider material, size, printing, order quantity, quality, and cost.

- Laminate tubes come in two types: Aluminium Barrier Laminate (ABL) and Plastic Barrier Laminate (PBL), each offering unique protective properties.

- Customization options include various tube sizes, shapes, closures, and printing techniques to enhance branding.

- Sustainability matters; using recyclable materials and adhering to regulations helps manufacturers and meets customer demand.

- Choosing a reliable supplier, like Xinfly Packaging, ensures quality, compliance, and better cost management for laminate tubes.

Material Choice for Laminate Tubes

Picking the right material for laminate tubes is important. It helps keep your product safe and saves money. You should think about how each material works for your product. The material can change how long your product lasts, how it looks, and if it is safe.

Types of Laminate Materials

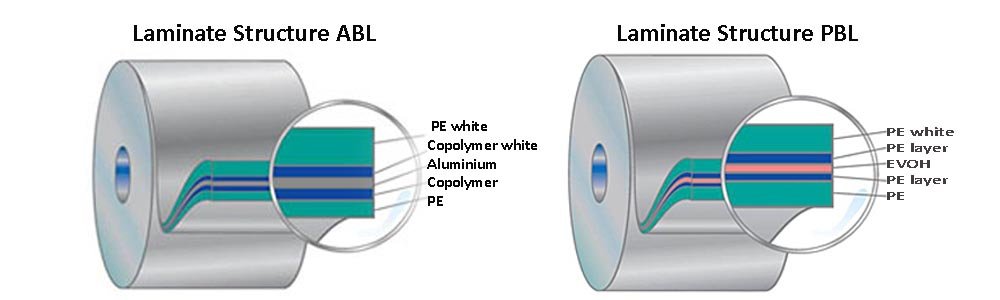

ABL vs. PBL

There are two main types of laminate tubes you can buy. Aluminium Barrier Laminate (ABL) and Plastic Barrier Laminate (PBL) are the most used. ABL tubes have layers of polyethylene and aluminum foil. These layers give strong protection from light, water, and air. PBL tubes use ethylene vinyl alcohol (EVOH) to block gases. This keeps products fresh for longer. In 2024, laminate tubes are expected to have a 40.87% market share. Many personal care and cosmetics brands pick these tubes. They look nice and keep products safe.

- Laminated tubes mix plastic and metal-like barrier benefits.

- ABL tubes protect sensitive products from outside things.

- PBL tubes block gases and work for many formulas.

- Personal care used 42% of all tubes in 2023.

- The pharmaceutical segment is growing fast at 7.1% CAGR until 2032.

Barrier Properties

Barrier properties show how well tubes protect what is inside. You want tubes that stop water, air, and light from getting in. This makes your product last longer and stay good.

| Material Type | Barrier Properties | Shelf Life Impact |

|---|---|---|

| Laminated Films | Stops water, air, and light very well | Makes sensitive products like dried barberries last longer |

| Metalized Films | Great barrier with little extra thickness | Keeps food like tomato powder and walnuts fresh |

| Multilayer Plastics | Mixes good features for best results | Walnuts can stay good for 12 months |

If you pack sensitive items, pick tubes with strong barrier protection. These tubes keep your product safe from air and water.

Quality Standards

Certifications

You should check for certifications when buying laminate tubes. Certifications prove the supplier follows safety and quality rules.

| Key Criteria | Description |

|---|---|

| Scalability | Can handle more orders without losing quality or breaking rules. |

| Regulatory Compliance | Follows laws and avoids legal trouble. |

| Innovation Capability | Can use new materials and technology. |

| Long-term ROI | Saves money over time and helps your brand. |

Trusted Suppliers

Pick suppliers who care about quality and being reliable. Xinfly Packaging is a trusted supplier for laminate tubes. They use strong materials and give great barrier protection. Their tubes meet strict quality rules and always work well.

- Material integrity means the layers stay together and do not peel.

- Barrier performance is key for cosmetics and medicines.

- Print quality should be clear and last long.

- Tube consistency means every tube works the same way.

- Safety and compliance are needed for food and cosmetic packaging.

Xinfly Packaging helps you by giving quality tubes and meeting all big certifications.

Product Compatibility

You need to match the tube material to your product. This keeps your product safe and looking good. Different materials protect in different ways. Aluminum blocks light, water, and air. This is best for sensitive products. Inside coatings stop reactions with strong products. You should check if the tube resists chemicals and works with your formula.

- Aluminum protects sensitive products from outside things.

- Inside coatings stop reactions with strong formulas.

- You must check for chemical resistance and fit.

Laminated tubes are good for semi-solid products. They keep your product safe until the end. Many layers, including aluminum, block water and air. This helps your product stay fresh and work well.

Tip: Always test your product with the tube before a big order. This helps you avoid problems with how your product looks or works.

By picking the right material, you protect your product and make customers happy. You also save money and follow industry rules. Xinfly Packaging gives you good laminate tubes and expert help.

Tube Size and Design

Choosing the right tube size and design helps you create packaging that works well and looks great. The size and shape of your tube can change how people use your product and how they see your brand. When you match the tube to your product, you make it easier for customers to use and enjoy.

Sizing for Product Needs

Standard Sizes

Many brands use standard tube sizes because they fit most products and are easy to find. The 51 to 100 ml tube size is the most popular in the laminated tube market. You often see this size in personal care, cosmetics, and pharmaceutical products. This size gives enough volume for longer use and helps prevent waste. The compact design makes it easy to carry for travel or daily routines. Laminated tubes in this range are easy to squeeze, so users can get the right amount every time.

- 51 to 100 ml tubes are common for creams, gels, and lotions.

- These tubes work well for both home and travel use.

- The size helps keep products fresh until the last drop.

Custom Dimensions

Sometimes, your product needs a special size. Custom dimensions let you pick the exact tube size and volume that fits your formula. You can choose a tube that stands out on the shelf or fits a unique product. Custom tubes help you meet special needs, like single-use samples or large family packs.

Tip: Custom sizes can help your brand look different and meet special customer needs.

Tube Packaging Shape

Consumer Preferences

The shape of your tube changes how people feel about your product. A tall, skinny tube can look elegant and works well for high-end health and skincare items. A short, wide tube feels practical and is easy to hold, which many people like for hand creams. The right shape can make your product more appealing and easier to use.

Application-Specific Designs

You can design tubes for special uses. For example, a tube with a slanted tip works well for lip balms. A nasal tube shape fits medical gels. These designs help customers use your product the right way and add value to your brand.

Closures and Features

You have many options for closures and extra features. The table below shows some of the most requested choices:

| Customization Option | Description |

|---|---|

| Material Options | Choose from ABL, APT, PCR APT, and PBL for different needs. |

| Head Styles & Caps | Pick screw on, nasal, lip slant, or tamper-evident caps. |

| Decoration Techniques | Use offset printing, silk screening, or flexographic printing for unique looks. |

Other popular features include:

- Hot air tube sealing for fast and strong seals.

- High frequency sealing for special layers.

- Ultrasonic tube sealing for certain packaging needs.

When you pick the right tube size, shape, and features, you make your product easy to use and help your brand stand out. Customization lets you match your packaging to your product and your customers’ needs.

Printing and Customization

Printing and customization change how your tube packaging looks. You can pick from many printing styles and finishes. These choices help your packaging stand out. They also help your packaging match your brand.

Printing Complexity

Techniques

You have different ways to print on tubes. Basic printing uses one or two colors. This is good for simple designs and costs less money. If you want more colors or cool effects, you can use advanced printing. These include metallic inks, color blends, or designs that wrap all around. Hot stamping, embossing, and debossing add shine and texture. Soft-touch or matte varnish makes the tube feel smooth. Holographic or special foil finishes make the tube look fancy.

| Printing Complexity | Cost Level |

|---|---|

| 1–2 color basic printing | cheapest |

| 4+ color printing | moderate cost |

| Metallic inks, gradients, or full-wrap | higher |

| Hot stamping, embossing, debossing | premium |

| Soft-touch or matte varnish | premium |

| Holographic or custom foil | highest tier |

Cost Impact

Printing styles change how much tubes cost. Simple designs with fewer colors are cheaper. Adding more colors or special finishes makes the price go up. Fancy effects like embossing or holographic foil cost the most. You should think about your design and your budget. If you want a fancy look, you will pay more for printing.

Tip: Pick a printing style that fits your brand and budget. You can start with simple printing and add more as your brand grows.

Branding Options

Color Matching

Color matching helps your tubes look the same every time. You want your brand colors to always look right. Good color matching helps people trust your brand. It also makes your products easy to spot.

Design Consistency

Design consistency means your tubes always look alike. Use the same logo, colors, and style for all your products. This helps customers remember your brand.

- Custom branding lets you make designs for each product.

- You can use eco-friendly inks for a greener look.

- Fancy finishes like foil stamping and Spot UV make tubes pop.

- Matte and gloss lamination give different feels to your tubes.

- Cap and lid styles add style and function.

- Textures and custom inserts make your brand more interesting.

- Sustainability options let you mix luxury and eco-friendly choices.

Custom Features

Custom features help your tubes stand out in stores. Many people like products made just for them. Brands now offer more ways to customize tubes. You can pick special shapes, sizes, and printing styles. Advanced printing, like holographic and metallic finishes, make tubes look fancy. These features help you connect with your customers and build your brand.

- Custom options let you make tubes for your customers.

- Special shapes and sizes make your products easy to find.

- Good print quality keeps your design looking sharp.

- Fancy finishes make your tubes feel special and get attention.

Xinfly Packaging gives you lots of printing and finishing choices. You can work with their team to make tube packaging that fits your brand and goals.

Supplier Evaluation for Sourcing Laminate Tubes

Picking the right supplier is very important. You want someone who gives good quality and delivers on time. The supplier should help your brand grow. Here are the main things to check when you look at laminate tube suppliers.

Experience and Reputation

Industry Focus

Check if the supplier knows your market. Some suppliers work with health and skincare. Others work with food or medicine. A supplier with experience in your field helps you avoid mistakes. They also know special rules for your products.

Client Feedback

Client feedback shows how well a supplier does their job. Look for reviews and stories from other customers. Happy customers mean the supplier is reliable and solves problems quickly. You can ask for samples to see the quality before you buy.

| Criteria | Description |

|---|---|

| Technical Capability | Follows rules like ISO 9001 and uses good materials. |

| Quality Standards | Checks quality during making and tests for barrier and print. |

| Customization Options | Can make special sizes, closures, and printing. |

| Reliability Metrics | Delivers on time and handles changes in order size. |

| Supplier Responsiveness | Answers questions fast and fixes problems quickly. |

| Market Experience | Works with your market and can show samples. |

Tip: Suppliers with strong skills and good feedback help your packaging stand out.

Production Capacity

Lead Times

Production capacity means how many tubes a supplier can make. If they make a lot, you get your order faster. This helps you avoid waiting too long.

MOQs

Minimum order quantities (MOQs) are the smallest amount you can buy. Some suppliers need big orders, which may not work for small brands. Others let you order less, so you get what you need.

| Impact of Production Capacity | Effect on Lead Times | Effect on Order Fulfillment Reliability |

|---|---|---|

| High Production Capacity | Makes orders faster | Makes delivery more reliable |

| Limited Production Capacity | Slows down orders | Can cause you to run out of stock |

Ask about lead times and MOQs before you order. This helps you plan and keeps your products in stock.

Location and Logistics

Shipping Costs

Where the supplier is located changes shipping costs. Suppliers near ports or railways can ship for less money. Shorter trips mean lower transport costs.

Delivery Times

Location also changes how fast you get your order. Suppliers close to you can deliver faster. Good order handling at the supplier’s site helps speed up delivery.

- Supplier location can lower shipping costs if close to ports or railways.

- Being nearby means less travel and cheaper shipping.

- Fast order processing at the supplier helps you get products sooner.

Xinfly Packaging: A Global Supplier

Xinfly Packaging is a top supplier for laminate tubes. They work with over 1,200 beauty brands around the world. You get factory prices and can save 10-30% compared to others. Xinfly’s standard lead time is 21 days, and rush orders take 15 days. Their quality control is strict with ISO 9001:2015 and triple checks. They make over 50 million tubes each year. You can choose eco-friendly and custom tube options.

| Feature | Xinfly Packaging | Other Suppliers |

|---|---|---|

| Global Reach | Trusted by 1200+ beauty brands worldwide | Depends on the supplier |

| Pricing | Factory prices, save 10-30% | Often higher because of middlemen |

| Lead Time | 21 days standard, 15 days rush | Usually longer |

| Quality Control | ISO 9001:2015, triple checks | May be less strict |

| Production Capacity | Over 50 million tubes yearly | Can be much less |

| Customization Options | Eco-friendly and custom tubes | Fewer choices |

Note: Picking a supplier like Xinfly Packaging gives you fast service, quick delivery, and strong support.

If you check these things, you can find the best supplier for laminate tubes. This helps you get good packaging, save money, and grow your business.

Certifications and Service

When you pick a laminate tube supplier, you should check their certifications. Certifications mean the supplier follows important rules for safety and quality. These certificates help you trust that the tubes will protect your products. They also show the tubes meet laws in different countries.

Some important certifications to look for are:

| Certification | Description |

|---|---|

| ISO 17025 Laboratory Accreditation | Shows the supplier tests tube size and strength the right way. |

| ISO 9001 Certification | Proves the supplier uses a strong system for quality. |

| RoHS Compliance | Makes sure the tubes do not have unsafe chemicals. |

| REACH Compliance | Confirms the tubes are safe for people and nature. |

| PED Certification | Meets rules in Europe and the UK for pressure equipment. |

| Conflict-Free Sourcing | Follows the Dodd-Frank Act to avoid materials from conflict areas. |

Tip: Always ask your supplier for copies of their certifications. This helps you avoid trouble with customs or product recalls.

Certifications are more than just papers. They show the supplier cares about safety and quality. For example, ISO 9001 means the supplier checks every step, from start to finish. RoHS and REACH prove the tubes are safe for cosmetics, food, and medicine. PED certification matters if you sell in Europe or the UK. Conflict-Free Sourcing means the supplier uses safe and fair materials.

Good service is also very important. You want a supplier who answers fast and helps you solve problems. Good service means:

- Quick replies to emails and calls.

- Clear updates about your order.

- Help with design, printing, and shipping.

- Support after you get your tubes.

A supplier with strong service makes your work easier. You can fix problems faster and keep your customers happy.

Xinfly Packaging is special because they have top certifications like ISO 9001. They follow strict safety rules. Their team gives you quick help and expert advice. You get support at every step, from picking tubes to getting your order on time.

Picking a supplier with the right certifications and good service keeps your brand safe and helps your business grow.

Cost and Order Quantity

Understanding cost and order quantity helps you make smart choices for tube packaging. The price you pay depends on several factors, including the materials, design, printing, and how many tubes you order. Knowing these details lets you balance quality and budget.

Pricing Factors

Material and Design

The materials you choose for tube packaging affect the price. If you pick eco-friendly options, like recycled materials or post-consumer resins, you may pay more at first. However, these choices help your brand stand out and meet customer demand for sustainable packaging. You also need to think about the design. Simple shapes and standard sizes usually cost less. Custom shapes or extra features, such as special caps or unique finishes, can raise the price.

- Sustainable packaging is in high demand and can increase costs.

- Using recycled materials supports the environment and meets new rules.

- Fluctuating prices for plastics and aluminum can change your costs.

- Government rules about plastic use may affect your choices.

Printing Complexity

Printing is another big part of the cost. Simple designs with one or two colors are cheaper. If you want more colors, metallic inks, or special effects, the price goes up. Advanced printing methods, like embossing or holographic finishes, add to the cost. You should match your printing needs to your budget and brand goals.

Order Volume

Bulk Discounts

How many tubes you order changes the price per tube. If you order a large amount, you get a lower price for each one. Bulk orders can save you up to 40%. For example, if you order 50,000 tubes, you might pay $0.10 each. If you only order 1,000 tubes, the price could be $0.25 each. Ordering more at once helps you save money.

MOQ Impact

Suppliers often have a minimum order quantity (MOQ). This is the smallest number of tubes you can buy. If you cannot meet the MOQ, you may pay more per tube. Always ask about the MOQ before you order. This helps you plan your budget and avoid surprises.

Negotiating Terms

Payment Options

You can talk with suppliers about payment terms. Set clear goals before you start. Ask about flexible payment options, such as paying in parts or after delivery. This builds trust and helps you manage your cash flow.

Shipping Arrangements

Shipping is a big part of the total cost for tube packaging. You can use third-party logistics to make delivery faster and cheaper. Compare different suppliers and ask for the best shipping deals. Building a good relationship with your supplier can help you get better terms in the future.

Tip: Always compare offers from different suppliers. Look for bulk discounts, flexible payment plans, and good shipping options. This helps you get the best value for your tube packaging.

By understanding these cost factors, you can make smart choices. You get quality tube packaging that fits your budget and supports your brand.

Compliance and Sustainability

You must care about compliance and sustainability when buying laminate tubes. These things keep your brand, customers, and the earth safe. Many countries have strict packaging rules. You need to follow these rules to sell safely and avoid trouble.

Regulatory Standards

FDA, EU, Others

The European Union made a rule called Packaging and Packaging Waste Regulation (PPWR). This rule will start in August 2026. It wants to lower packaging waste in all industries, even healthcare. PPWR tells companies to use packaging that can be recycled, has recycled parts, and makes less trash. The United States does not have a rule like this for laminate tubes yet. Always check the newest rules in your area.

Documentation

You must keep good records to show you follow the rules. This means saving test reports, certificates, and proof of recycled content. Good records help you pass checks and avoid customs delays. They also help your customers trust you.

Tip: Always ask your supplier for new certificates and test results. This helps you show your tubes are safe and follow the rules.

Eco-Friendly Tube Packaging

Recyclable Materials

Many brands now use tubes made from recyclable materials. About 44% of new laminate tubes can be recycled. Over 60% of shoppers want brands to use recyclable or biodegradable packaging. If you pick these tubes, you show you care about the earth and your customers.

Sustainable Practices

Laminate tube makers use many ways to help the planet:

- They use lighter, all-plastic tubes instead of thick plastic ones.

- They add post-consumer recycled (PCR) and post-industrial recycled (PIR) materials.

- They use bio-based plastics made from waste oils.

- They design tubes that use up to 10% less plastic but stay strong.

- They make tubes that can be recycled in many waste streams.

- Aluminum tubes can be recycled again and again, saving energy.

- Plastic and laminate tubes can be recycled or burned for energy.

Xinfly Packaging is a leader in eco-friendly tube packaging. They offer tubes made with recyclable and bio-based materials. Their team helps you choose the best green options for your brand.

Traceability

Traceability means you can track your tubes from the factory to the store. This keeps your products safe. You can find and recall items fast if there is a problem. Traceability also protects your brand from fake products and theft. This matters a lot for luxury and cosmetic brands.

- Traceability lets you follow your tubes through the supply chain.

- It helps you follow global rules and keep products safe.

- Certifications from your supplier prove you follow the rules.

- Working with certified suppliers like Xinfly Packaging makes compliance easier and improves quality.

You should always pick suppliers who care about safety and following the rules. This keeps your products safe, your customers happy, and your brand strong.

You can make better choices if you follow these steps for getting laminate tubes. Think about the material, tube size, printing, supplier, cost, and rules. Use this list to check each thing when picking tube packaging. This helps you not make mistakes and find the best tube packaging. If you need help, contact Xinfly Packaging. Their team can help you pick the right tube packaging for what you need.

Check how you get laminate tubes now and make your tube packaging better for good results.

Frequently Asked Questions

Key points for smarter laminate tube sourcing in 2025 – PBL vs ABL structures, barrier levels, decoration, MOQ, lead time, supplier vetting, cost control and sustainability options.

Q1What is a laminate tube and when should I use it?

Q2What is the difference between ABL and PBL laminate tubes?

Q3What are the key steps to smarter laminate tube sourcing?

1) Define formula needs – barrier level, filling process, region approvals.

2) Choose structure – ABL vs PBL vs mono-PE.

3) Align on print & finish – offset/silk-screen, foil, matte/gloss.

4) Confirm MOQ & lead time – and check supplier capacity.

5) Lock QC standards – leak test, sealing, color targets and visual defects.

Q4How do laminate tubes compare in cost to standard PE tubes?

Q5What decoration and printing options are available for laminate tubes?

Q6Are laminate tubes compatible with sustainable packaging goals?

Q7What is a typical MOQ and lead time when sourcing laminate tubes?

Q8How do I check laminate tube quality before placing a big order?

Q9Which information should I send to a supplier for a fast laminate tube quote?

Q10How can Xinfly Packaging support smarter laminate tube sourcing?

Want a smarter laminate tube sourcing plan?

Share your formulas, markets and target volumes – Xinfly Packaging will design the right laminate tube structures, compare costs and send you a clear sourcing roadmap.