The reasons silk screen printing may fail on cosmetic packaging

You should know why silk screen printing can fail on cosmetic packaging. Bad print adhesion can make the decoration peel or come off. This damage changes how the product looks and feels. Customers might think the packaging is not good quality. This can hurt your brand’s reputation. Even small problems can get worse over time and make the packaging look less nice.

Key Takeaways

- Pick the correct ink for your packaging material. This helps the ink stick well and stops it from peeling.

- Make sure your printing area is always clean. This keeps the screen from getting dirty and helps prints look even.

- Use the same pressure and angle with your squeegee each time. This spreads the ink better.

- Get the surface of your packaging ready the right way. This helps the ink stick and keeps it from fading.

- Use strong quality checks to find problems early. This makes sure your prints are always good.

Causes of Failure in Silk Screen Printing

Ink and Cosmetic Packaging Mismatch

It is important to use the right ink for each packaging material. Glass and plastic are not the same. Glass needs ink that sticks well to its surface. Plastic, like PETE, can have trouble with ink sticking. Each material also has different scuff resistance. If you pick the wrong ink, the print may not stick or may have gaps. The ink must bond well to stop peeling or fading.

Tip: Always make sure the ink works with your packaging before printing.

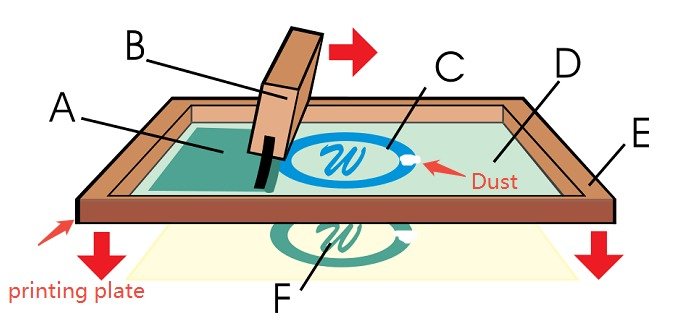

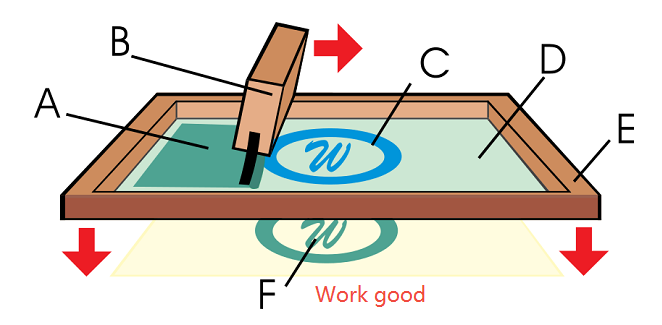

Screen Contamination

Dust, leftover ink, and small bits can get on the screen. These things block the mesh and cause missing spots in the print. You might see uneven prints or places where ink does not go through. Old ink or emulsion can stain the mesh and block it too. Cleaning the screen after each use helps stop these problems.

- Common contaminants:

- Dust

- Leftover ink

- Small bits

Note: Keeping your work area clean helps stop printing gaps and makes prints look better.

Squeegee and Pressure Issues

The squeegee helps move ink through the screen. Squeegees made of medium hardness polyurethane work best. The angle and pressure of the squeegee matter a lot. Use an angle between 45 and 75 degrees. Keep the pressure the same for even ink. Too much pressure can squeeze the screen too hard and cause gaps. Worn blades or the wrong hardness can also cause problems.

| Squeegee Issue | Effect on Printing |

|---|---|

| Worn blades | Uneven ink, printing gaps |

| Wrong hardness | Blurry lines, bad coverage |

| Pressure not steady | Gaps, uneven prints |

Ink Viscosity Problems

Ink viscosity is how thick or thin the ink is. If the ink is too thick, the screen may stick to the packaging. If it is too thin, the ink may spread too far. Thick ink can make the print crack. Thin ink can leave empty spots or gaps. You should mix and test the ink before you start printing.

Tip: Change the ink thickness to fit your design and packaging for better prints.

Material Impurities

Materials like silica sand, soda ash, and limestone must be pure for good glass bottles. If they are not pure, the surface can be rough. Rough surfaces make it hard for ink to stick. You might see defects or gaps in the print. Always check your packaging materials before printing.

Design Flaws

Design mistakes can make silk screen printing fail. Thin or big patterns may not print right. Bubbles can form if you use the wrong additives. Thick ink can make the screen stick to the packaging. Prints can stay sticky if you do not cure them long enough. Bad ink can make the print peel off. Too much ink makes the print crack. Dirty screens or bad plates can mess up the pattern. Wrong squeegee angle or pressure can cause too much or too little ink. The wrong scraper hardness can blur lines. Thick ink can show the mesh pattern on glass.

- Bubbles from wrong additives.

- Screen sticks from thick ink.

- Sticky prints from not curing enough.

- Weak prints from bad ink.

- Cracked prints from too much ink.

- Pattern problems from dirty screens or bad plates.

- Gaps from wrong squeegee angle or pressure.

- Blurry lines from wrong scraper hardness.

- Mesh pattern shows from thick ink.

Air Bubbles

Air bubbles can show up during silk screen printing. These bubbles make gaps and uneven prints. You might see tiny holes or spots with no ink. Air bubbles often come from bad mixing or wrong additives. Mix the ink well and check for bubbles before printing.

Tip: Move slowly and mix well to stop bubbles and gaps.

Common Technical Issues Table

| Issue | Description |

|---|---|

| Bleeding | Ink spreads too far, often from too much ink or wrong screen distance. |

| Mesh Stains | Old ink or emulsion blocks the mesh and causes gaps. |

| Wrong Ink Usage | Using the wrong ink or not handling it right can hurt sticking and drying. |

| Screen Tension | Old screens can make colors wrong and images look weird. |

| Emulsion Breakdown | If emulsion breaks, designs can blur or ink can spread. |

Ink Adhesion Challenges

Surface Preparation

You need to prepare the surface of cosmetic packaging before printing. If you skip this step, ink adhesion will suffer. When the surface is not clean or treated, the ink may peel or fade. You might see non-adhesion, which means the print does not stick at all. This problem can ruin the look of your product.

- Proper surface treatment helps ink stick to the packaging.

- If you do not prepare the surface, you may see peeling and fading.

- Flame treatment raises the surface energy, making it easier for ink to bond.

- Poor treatment leads to weak adhesion and bad printing results.

You can use flame treatment to improve the surface. This method changes the surface so ink can grip better. Always check the packaging for dust, oil, or other dirt before printing. Clean and treat the surface to get the best results.

Tip: Always test the surface before printing. A simple water drop test can show if the surface is ready. If water beads up, you need more treatment.

Environmental Factors

The environment in your printing area affects ink adhesion. High humidity can slow down drying. Low temperatures can make ink thick and hard to use. If the air is too dry, ink may dry too fast and not bond well. You should control the temperature and humidity in your workspace.

Printing in the wrong conditions can cause defects. You may see cracks, gaps, or faded prints. Always monitor your workspace and adjust as needed. Good air flow and stable conditions help you get better printing results.

Note: Keep a log of your printing environment. Regular testing helps you spot problems early and fix them before they affect your prints.

Prevention and Best Practices for Cosmetic Packaging

Material and Ink Selection

It is important to pick the right materials and inks. The surface of each bottle or container changes how colors look and stick. If the surface is smooth and even, prints turn out better. You will see fewer missing spots. Mixing ink the right way helps keep colors bright and stops problems. Screen printing gives bright colors and sharp designs. But you need to match the ink and material for good results. Some brands, like Xinfly Packaging, sell good inks and packaging. Their products help stop printing problems. Their knowledge helps prints stick well and last, even when touched a lot.

- Use water-based or low-solvent inks to lower risks.

- Choose substrates that work with your ink for better sticking.

- Store chemicals safely and teach staff how to use them.

- Make sure your printing area has good air flow.

Equipment Maintenance

You must keep your equipment clean and in good shape. Dirty screens or squeegees can mess up prints and leave gaps. Always check your equipment before you start. Clean screens and squeegees after every use. Oil moving parts and look for damage. Automatic machines and tools that are very exact help you get even prints and better sticking.

| Maintenance Procedure | Benefit |

|---|---|

| Use of UV cured inks | Makes prints last longer and not fade |

| Surface treatment before printing | Helps ink stick better for good prints |

| Automatic screen printing machines | Gives even prints every time |

| High-precision screen printing equipment | Makes prints more exact |

| Optional topcoat finishes | Protects the printed surface |

Quality Control Steps

You need to follow strict steps to stop defects in packaging. Check if the color matches your design. Look at each print for clear lines and details. Watch for smudges, missing spots, or ink outside the lines. Test prints after they dry and wash them a little to see if they last. Check every batch to make sure they all look the same. Adjust your machines often to keep prints good. Good rules and checking help you find problems early. Many companies check three times: raw materials, during making, and after finishing. Training workers well also helps stop mistakes. When your team knows what to do, you get better prints and fewer errors.

Tip: Good checking and regular tests help you make customers happy and keep your packaging looking nice.

You can stop most silk screen printing problems if you know the main reasons. These reasons include ink mismatch, dirty screens, and not preparing the surface well. If you use good steps and check your work, your prints will look nice and last longer.

- Silk screen printing makes packaging look bold and fancy.

- Thick ink gives bright colors and helps stop scratches or fading.

- Cool designs make your product easy to notice and help your brand grow.

Use these ideas to get strong and good prints every time.

Why SilkScreen Printing May Fail on Cosmetic Packaging – FAQs

Understand the common causes of silk-screen printing failures: ink compatibility, surface treatment, substrate issues, environmental factors, machine settings and quality-control steps for cosmetic tubes & bottles.

1) What causes the most print failures during silk-screen production?

2) Why is surface treatment so critical?

3) How does equipment and setting affect quality?

4) Can environmental conditions sabotage printing?

5) What design or substrate flaws often contribute to failure?

6) How do you prevent air-bubbles or ink defects?

7) What are the best quality control steps?

8) Why invest in on-substrate proofs?

9) When should I reconsider silk-screen and maybe choose another method?

10) How can this benefit my brand’s packaging?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.