How Cosmetic Tubes Are Manufactured Step by Step

When you choose a cosmetic tube manufacturer, you want safe packaging. You also desire packaging that is high-quality. Every step in making tubes is crucial. Manufacturers use strong quality checks and machines. This helps keep products safe and trustworthy. You can see how each step aids in protecting the product. Each step also contributes to keeping people safe.

| Evidence Description | Impact on Quality and Safety |

|---|---|

| Quality control checks happen during production. | Keeps people safe and lowers recalls, building trust. |

| Machines fill and pack tubes automatically. | Keeps products safe, shares brand info, and follows rules. |

| Careful QC checks happen at every stage. | Checks for safety, quality, and rules, stopping problems. |

| ISO 22716 Quality Control rule. | Makes sure products stay the same by checking and writing down details. |

Key Takeaways

- Picking the right cosmetic tube maker keeps your products safe and high-quality.

- Choosing the material is very important. Plastics, aluminum, and laminates each help protect your product and show off your brand in different ways.

- The extrusion process shapes plastic into tubes. This makes sure all tubes look the same and are good for making many at once.

- Heading and capping are key steps. They keep the product inside the tube and make it easier to use.

- Decoration uses printing and labeling. This helps your product get noticed and tells buyers important things.

- Sealing methods like heat and ultrasonic sealing keep the product clean and fresh for longer.

- Quality control checks happen at every step. These checks find problems early and make sure the final product is good.

- Following industry rules and standards helps people trust your brand and keeps your brand’s good name.

Material Selection

Picking the right material is the first step. You must think about how the tube looks. You also need to consider how it protects the product. The environment matters too. The material you pick changes how the tube works. It also affects how customers see it.

Types of Materials

Plastics

Plastic tubes are used most for cosmetics. In 2025, they will make up 64% of the market. Polyethylene (PE) and polypropylene (PP) are common plastics. Plastic tubes are light and cheap. They can be made in many shapes. Decorating them is easy. But, they may not block air or water well. Extrusion makes plastic tubes smooth and even. This is good for making lots of tubes.

Aluminum

Aluminum tubes protect products very well. They keep out air, light, and water. This helps creams and ointments stay safe. Aluminum tubes can be recycled. They do not react with chemicals. Aluminum tubes cost more than plastic ones. They are harder to design in different ways. The extrusion process for aluminum is not the same as for plastics. It still makes strong and safe tubes.

Laminates

Laminated tubes have layers of different materials. These layers can be plastic and aluminum. Laminates are strong and block air and water. They are good for products that need to stay clean. Laminated tubes help products last longer.

Importance of Material Choice

The material you pick does more than change how the tube looks. It keeps products safe and fresh. It also helps your brand look good.

Using good materials keeps your product safe. It stops bad chemical reactions. It keeps the inside fresh. It blocks air and light from getting in.

Here are some things to think about when picking a material:

| Factor | Description |

|---|---|

| Target Audience | How the package looks to buyers. |

| Brand Alignment | How the material matches your brand. |

| Regulations | If the package follows the rules. |

| Shipping | If the material keeps products safe when moving. |

| Flexibility | If the package works for different ways to use the product. |

| Sustainability | If the material can be reused or recycled. |

You should think about how your choice affects the planet. Plastics like PP and HDPE often hurt the planet less than some other materials. Using recycled materials lowers pollution. Recycling tubes is better than throwing them away.

Picking the best material keeps your product safe. It helps your cosmetics last longer. It also helps your brand get noticed.

Plastic Tube Manufacturing Process

When you look at the production of cosmetic tubes, you see that the plastic tube manufacturing process starts with extrusion. This step shapes the tube and sets the foundation for the rest of the production. You will find that the process is especially important for high-volume production, where speed and accuracy matter.

Extrusion

Extrusion is the first big step in the production of cosmetic tubes. You use this method to turn raw plastic into long, hollow tubes. The process uses precision extrusion techniques to make sure every tube is the right size and shape.

Melting

You begin by feeding plastic pellets or granules into a machine called an extruder. The extruder heats the plastic to its melting point. Each type of plastic, like polyethylene or polypropylene, melts at a different temperature. You must keep the temperature just right so the plastic flows smoothly. Most plastics melt between 320°F and 500°F. The pressure inside the extruder can reach up to 10,000 psi, but most of the time it stays between 1,000 and 5,000 psi. This high pressure pushes the melted plastic forward.

Shaping

Once the plastic melts, you push it through a special mold called a die. The die shapes the melted plastic into a long, continuous tube. This step is called cosmetic tube extrusion. You can make tubes with one layer or several layers. If you make a single-layer tube, you use just one type of plastic. This method is simple and fast. If you want a tube with two or five layers, you use co-extrusion. Co-extrusion combines different plastics in layers. This makes the tube stronger and helps it block air and water better. Multi-layer tubes look better and protect the product inside for longer.

Cooling

After shaping, you must cool the tube quickly. You move the hot tube through a water bath or use cool air. This step makes the tube hard and keeps its shape. If you skip this step or do it wrong, the tube can bend or lose its form. Cooling is important for every tube, no matter how many layers it has.

Tip: Keeping the right temperature and pressure during extrusion helps you avoid defects and waste.

Tube Cutting

When the tube cools and hardens, you need to cut it into the right lengths. You use special machines for this job. These machines cut each tube to the exact size you want. This step is key for the production of cosmetic tubes because it gives you tubes that all look the same. Uniform tubes help your product look neat and professional. Cutting with machines also means you get the same size every time, which is important for both how the tube works and how it looks.

- The tube cutting process uses sharp blades and sensors.

- Machines measure each tube before cutting to make sure every piece matches your needs.

- This level of precision in cutting is vital for the production of cosmetic tubes, especially when you want to keep your brand’s look consistent.

You can see that the plastic tube manufacturing process uses advanced machines and careful steps. Each part of the process, from melting to cutting, helps you get high-quality tubes. When you use these methods, you make sure your cosmetic products stay safe and look great on the shelf.

Heading

After you cut the plastic tubes, you move to the heading stage. This step shapes the top of the tube. The heading process gives the tube its final form and prepares it for decorating and capping. You need to choose the right method for heading because it affects how the tube works and looks.

Methods

You can use two main methods for heading: injection and compression. Each method has its own benefits. Your choice depends on the type of tube and the product you want to fill.

Injection

In the injection method, you use a machine to inject melted plastic into a mold at the end of the tube. The mold shapes the head of the tube. You can make different shapes and sizes with this method. Injection heading works well for tubes that need special designs or strong necks. You get a smooth finish, which helps when you start decorating the tube. This method also lets you add features like threads for screw caps or special openings for easy use.

Compression

Compression heading uses a different approach. You place a small piece of plastic, called a slug, on the end of the tube. Then, a machine presses the slug into shape. The pressure forms the head and seals it to the tube body. Compression heading works best for simple tube shapes. You get a strong bond between the head and the tube. This method is fast and cost-effective, especially for high-volume production. After compression, you can move on to decorating the tube.

Structural Importance

The heading step is very important for the strength and function of your cosmetic tube. A well-made head keeps the product safe inside. It also makes sure the cap fits tightly. If you skip proper heading, the tube may leak or break. You want the tube to look good and work well, especially after decorating. The heading process also helps the tube stand up straight on shelves, which makes your product look more appealing.

Tip: Always check the heading for cracks or weak spots before decorating or filling the tube.

A good heading process helps you get a tube that is ready for decorating and capping. You can trust that your product will stay safe and look great. When you focus on heading, you set the stage for the next steps in making a high-quality cosmetic tube.

Decoration Process

You want your cosmetic tubes to look nice and get noticed. The decoration step is when you add color, pictures, and words to each tube. This helps your product stand out and show your brand.

Printing

Printing puts images and text on cosmetic tubes. There are different ways to print, and each has its own good points.

Offset

Offset printing makes clear pictures and keeps colors the same. It is used for fancy cosmetic products with detailed designs. Offset printing is fast and saves money when making lots of tubes. You get smooth and professional tubes every time.

Silk Screen

Silk screen printing gives bright and bold colors. It is great for strong designs or colored tubes. Silk screen printing lasts a long time and is good for small orders or special designs. You can use it for raised letters or shiny looks.

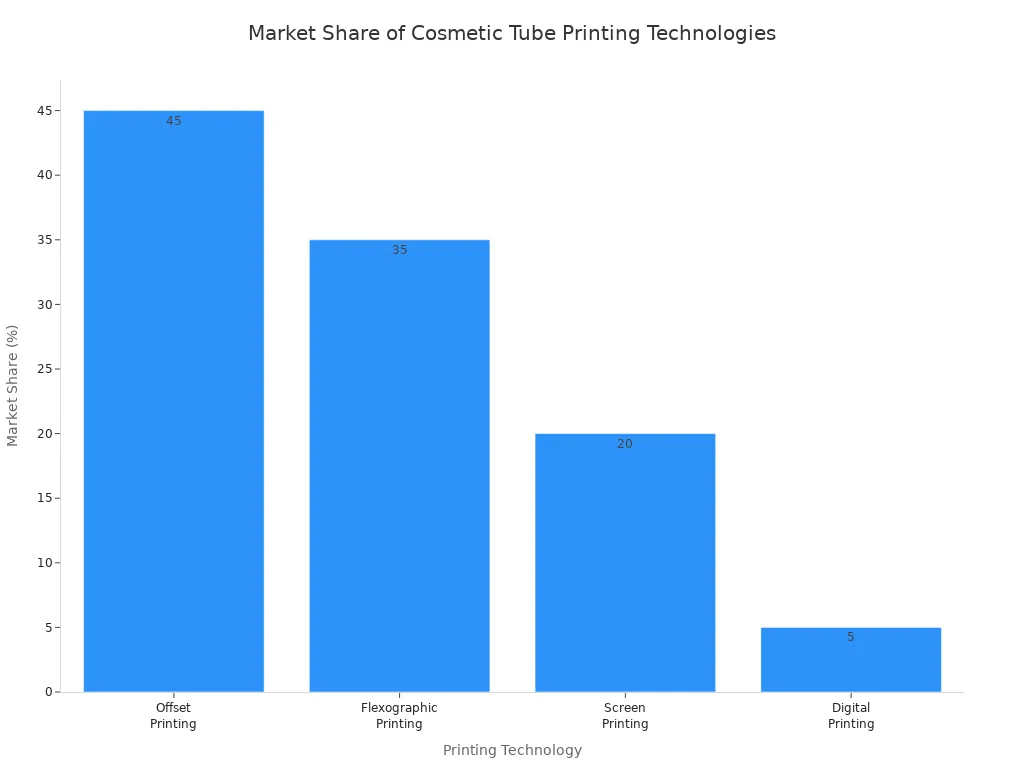

Here is a table that shows the most common printing types for cosmetic tubes:

| Printing Technology | Advantages | Applications | Market Share | Trend |

|---|---|---|---|---|

| Offset Printing | High Resolution and Image Quality, Excellent Color Consistency, Cost-Effectiveness for Large Runs | Premium cosmetic products requiring high-definition graphics | 45% | Maintains popularity due to print quality and color accuracy. |

| Flexographic Printing | High-Speed Production, Versatile Ink Options, Material Flexibility | Mid-range cosmetic products needing cost efficiency | 35% | Cost-effectiveness and versatility drive widespread use. |

| Screen Printing | Vibrant and Opaque Colors, Durability, Customization | Small production runs and bespoke designs | 20% | Rising trend towards customization boosts demand. |

| Heat Transfer Printing | High-Quality Images, Non-Contact Printing, Complex Designs | Products requiring high-impact visual appeal | N/A | Increasing demand for visually appealing packaging drives adoption. |

| Digital Printing | No Plate Requirement, Cost-Effective for Short Runs, High Flexibility | Limited editions and personalized products | 5% | Growing trend towards personalization and limited editions drives increased adoption. |

Tip: Picking the best printing way makes your product look neat and keeps your brand colors the same.

Labeling

Labeling is an important part of decorating. Labels show the product name, what is inside, and safety notes. Labels help people know what they are buying and how to use it. The FDA’s 21 CFR Part 701 says you must list ingredients clearly and not mislead people. Labels must also follow the law in every place you sell. If you do this, you protect your brand and keep buyers safe.

Branding

Branding makes your cosmetic tube special. You use decoration to give your tube a look that matches your brand. Water transfer printing and digital printing help you make tubes that stand out. You can add special touches, bright pictures, or clear spots to see the product inside. These ideas help your product tell a story and connect with people.

Here are some ways decoration helps branding and selling:

- Decoration makes your product look better.

- Special decoration helps your tube get noticed.

- Good decoration makes people trust your brand more.

| Innovation Type | Description | Impact on Consumer Perception |

|---|---|---|

| Tactile Packaging | Soft matte finishes, combo varnish, and squeezability enhance sensory appeal. | Creates an immersive experience and strengthens emotional connections. |

| 360° Graphics | Bold, detailed graphics and luxury finishes improve shelf presence. | Helps products stand out and tells a deeper brand story. |

| Clear Packaging | Transparent materials allow product visibility. | Reinforces brand authenticity and builds consumer trust. |

| Circularity | Mono-material tubes and optional PCR content promote sustainability. | Meets consumer expectations for eco-friendly packaging solutions. |

Note: Xinfly Packaging has many decoration choices, like offset, silk screen, and digital printing. You can pick finishes and effects that fit your brand and product.

The decoration step is your chance to make a great first impression. When you use the right printing and labels, your product can do well in a busy market.

Capping

After the heading operation, you move to the capping stage. This step is where you add the cap to each tube. The right cap keeps your product safe and easy to use. You want to make sure the cap fits well and protects the contents until the sealing step.

Types of Caps

You can choose from several types of caps for cosmetic tubes. Each type has its own benefits and best uses. The table below shows the main types of caps and when you might use them:

| Cap Type | Description | Ideal Use Cases |

|---|---|---|

| Flip-Top Caps | Convenient for one-handed use, suitable for lotions and everyday products. | Lotions, cleansers, skincare products. |

| Screw Caps | Classic and secure, often used for premium lines. | Aluminum tubes, high-end skincare. |

| Disc-Top Caps | Push-button mechanism for easy dispensing. | Haircare products, thinner lotions. |

| Pump Caps | Best for high-viscosity formulas, offers controlled dispensing. | Thick creams, sunscreens. |

| Specialty Caps | Unique materials like wood or metal for high-end appeal. | Sustainable or luxury product lines. |

Screw

Screw caps give you a tight and secure closure. You twist them on and off. These caps work well for products that need extra protection. You often see screw caps on aluminum tubes and high-end skincare. They help keep air out and stop leaks before sealing.

Flip-Top

Flip-top caps let you open and close the tube with one hand. You just flip the lid up to use the product. These caps are great for lotions and cleansers. They make it easy to get the right amount out. Flip-top caps also help prevent spills and keep the tube clean until cosmetic tube sealing.

Application

In large-scale production, you use high-speed capping machines to put caps on tubes. These machines work fast and handle hundreds or even thousands of tubes each minute. The capping station lines up each tube and places the cap with precision. Machines adjust to different tube sizes and cap types, so you get a perfect fit every time. Sensors and vision systems check that each cap is present and tight. This step helps you avoid leaks and keeps your product fresh until sealing.

You want the capping process to be smooth and reliable. A good cap makes it easy for customers to use your product. It also keeps the contents safe from air and germs. The choice of cap affects how people feel about your product. A well-sealed cap helps your product last longer, especially if it contains natural ingredients. You protect your brand and your customers by making sure the capping and sealing steps work together.

Tip: Always check that the cap fits well before sealing. This helps prevent leaks and keeps your cosmetic tubes capping process efficient.

The capping step is key for both user experience and product safety. When you use the right cap and a reliable capping station, you set your product up for success in the market.

Sealing

After you cap your cosmetic tubes, you need to seal them. Sealing keeps your product safe inside the tube. It also stops air, water, and germs from getting in. You have a few ways to seal cosmetic tubes. Each method works well for different products and materials.

Methods

You can choose from several sealing methods. The most common are heat sealing and ultrasonic sealing. Each method has its own strengths.

Heat

Heat sealing uses high temperatures to melt the end of the tube. You press the tube between heated bars or plates. The plastic melts and fuses together. This creates a strong, leak-proof seal. You often use heat sealing for plastic tubes. It works fast and gives you a tight bond. You can also add a date code or batch number during this step. This helps you track your products.

- Heat sealing creates a secure bond.

- It prevents leaks and keeps out germs.

- You get a neat, flat end on each tube.

Ultrasonic

Ultrasonic sealing uses sound waves to seal the tube. The machine sends high-frequency vibrations into the plastic. The vibrations make the plastic heat up and melt. You do not need direct heat. This method works well for sensitive products that might get damaged by high temperatures. Ultrasonic sealing is clean and quick. It gives you a strong seal without burning or changing the tube’s look.

- Ultrasonic sealing is good for delicate formulas.

- It uses less heat, so it protects your product.

- You get a smooth, strong seal every time.

Here is a table that shows how different sealing types work and what they are best for:

| Sealing Type | How It Works | Best For | Pros | Cons |

|---|---|---|---|---|

| Heat Sealing | Melts and fuses tube ends with heat | Most plastic tubes | Strong, leak-proof, fast | Not for heat-sensitive products |

| Ultrasonic Sealing | Uses sound waves to melt and bond plastic | Sensitive or specialty products | No direct heat, clean, precise | Needs special equipment |

| Compression Sealing | Presses and bonds layers with pressure | Laminated tubes | Simple, effective | Less common for plastics |

Tip: Always pick the sealing method that matches your tube material and product needs. This helps you avoid leaks and keeps your product fresh.

Security

Sealing does more than close the tube. It protects your product and your customers. A good seal keeps out air, water, and dirt. This stops germs from getting in. It also keeps the product from drying out or losing its power.

- Induction sealing creates airtight barriers that block contamination, oxidation, and moisture.

- This step is key for keeping sensitive ingredients safe.

- Sealing stops air from reaching the product, so it lasts longer and works better.

You want your customers to trust your brand. A strong seal shows you care about safety and quality. When you use the right sealing method, you help your product stay fresh and effective until the last drop.

Quality Control

You want every cosmetic tube to be perfect for customers. Quality control helps you find problems early. This keeps your products safe. You check each step from start to finish. This process protects your brand and builds trust.

In-Process Checks

You use in-process checks to find defects fast. These checks help you fix issues before they get worse. Real-time monitoring and sensors watch every tube on the line.

| Feature | Description |

|---|---|

| Real-Time Monitoring | You watch tubes during production to catch defects right away. |

| High Precision | Sensors and smart tools find even tiny flaws. |

| Customizable Solutions | You adjust inspection systems to fit your needs. |

| Ease of Integration | You add these checks to your current machines easily. |

| Data Analytics | You collect and study data to improve your process. |

Automated vision systems and robots help lower human mistakes. These tools keep each tube strong and safe. You run drop, pressure, and leak tests to check for leaks. You also test for heat, cold, UV, and moisture resistance. These steps help you deliver quality products.

Tip: In-process checks save time and money by finding problems early.

Final Inspection

Before shipping, you do a final inspection. This step makes sure every tube meets your quality standards. You look for common defects that can hurt how your product looks or works.

| Defect Type | Description |

|---|---|

| Defective Aluminum Billets | Impurities or cracks in aluminum can cause weak tubes. |

| Extrusion Defects | Wrong pressure or temperature can make tubes look bad. |

| Surface Defects | Lines or marks can hurt the appearance of your tubes. |

| Welding Defects | Bad welding can make rough spots or weak areas. |

| Twists and Bends | Tubes may look crooked or have marks. |

| Scratches and Dents | These can happen during cutting or transport. |

| Stains or Oil Patches | Cutting can leave marks or stains on tubes. |

You also check that labels and barcodes are in the right spot. Adhesion tests make sure graphics do not peel or fade. You test random tubes for leaks and strength after production. This helps you keep your promise of quality.

You track each batch with special numbers. This traceability helps you fix problems fast if something goes wrong. You train your team to follow these steps and keep records with digital tools.

Standards

You follow strict standards to keep products safe and trusted. These rules guide you from start to finish.

- NSF/ANSI 455-3 Cosmetic GMP Certification helps you meet high safety and quality standards.

- ISO 22716 gives you steps for good manufacturing practices and quality assurance.

- You also follow FDA rules in the U.S. and global standards like REACH and GMP.

Meeting these standards helps you sell in new places and avoid recalls. It shows partners and customers you care about quality.

| Benefit Type | Description |

|---|---|

| Regulatory Compliance | You meet legal rules and avoid costly recalls. |

| Enhanced Market Trust | You show your commitment to safety and quality. |

| Risk Mitigation | You lower the risk of packaging failures and complaints. |

| Improved Quality Control | You get reliable and consistent results. |

| Impact on Brand Reputation | You build loyalty and protect your brand’s reputation. |

Note: Xinfly Packaging keeps improving and works with clients to meet new needs. You can trust your cosmetic tubes meet the highest standards for quality and safety.

You can see that each step in making tube packaging is important. The table below shows what each step does for the final product:

| Stage | Description |

|---|---|

| Raw Material Selection | You pick strong materials to keep tubes safe. |

| Extrusion and Formation | You shape tubes carefully so they work well. |

| Printing | You put clear designs on tubes that last a long time. |

| Capping | You close tubes tightly with the right cap. |

| Sealing | You make sure products stay safe inside the tubes. |

| Quality Assurance | You check every tube to make sure it is good. |

If you choose a good cosmetic tube manufacturer, your brand and product stay safe. A skilled manufacturer uses strong materials and checks every step. This keeps tubes safe and helps people trust your brand. Pick a company like Xinfly Packaging for expert help with tube packaging.

Cosmetic Tube Manufacturing – Frequently Asked Questions

From materials and extrusion/lamination to heading, printing, sealing and QC—here are the key steps, controls and timelines.

1) What materials are commonly used to make cosmetic tubes?

2) What’s the first step: extrusion or lamination?

3) What is “heading” and shoulder/neck forming?

4) How are graphics added—before or after heading?

5) Which printing and decoration methods are used?

6) How is colour accuracy controlled?

7) How are caps fitted and sealing done?

8) What quality tests are performed during production?

9) What are typical manufacturing tolerances?

10) How long does the whole process take?

11) How do you make tubes more sustainable?

12) What documents can a manufacturer provide?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.