Laminated Tubes Explained and Why They Matter

Laminated Tubes help protect things you use every day. You see these tubes in toothpaste, creams, and medicine. They have many layers to block oxygen, light, and water.

- The world market for these tubes will be about USD 4.03 billion by 2034.

- Their layers use plastic and aluminum for more safety.

| Material Type | Function |

|---|---|

| PBL (Plastic Barrier Laminate) | Keeps products safe, stops smells from escaping, often used in cosmetics. |

| ABL (Aluminium Barrier Laminate) | Gives better protection, used for sensitive medicine products. |

These tubes help products last longer than other packages. Their bendy shape and strong layers make them special.

Key Takeaways

- Laminated tubes keep products safe from air, light, and water. This helps products stay fresh for a longer time. These tubes are light and do not cost much. This makes them easy to move and store for companies. Laminated tubes have many designs and colors. This lets brands make packaging that looks nice. They follow strong safety rules. This keeps the products inside clean and safe for people. Picking products in laminated tubes helps the environment. Many tubes are made from recycled stuff.

Laminated Tubes Features

Structure

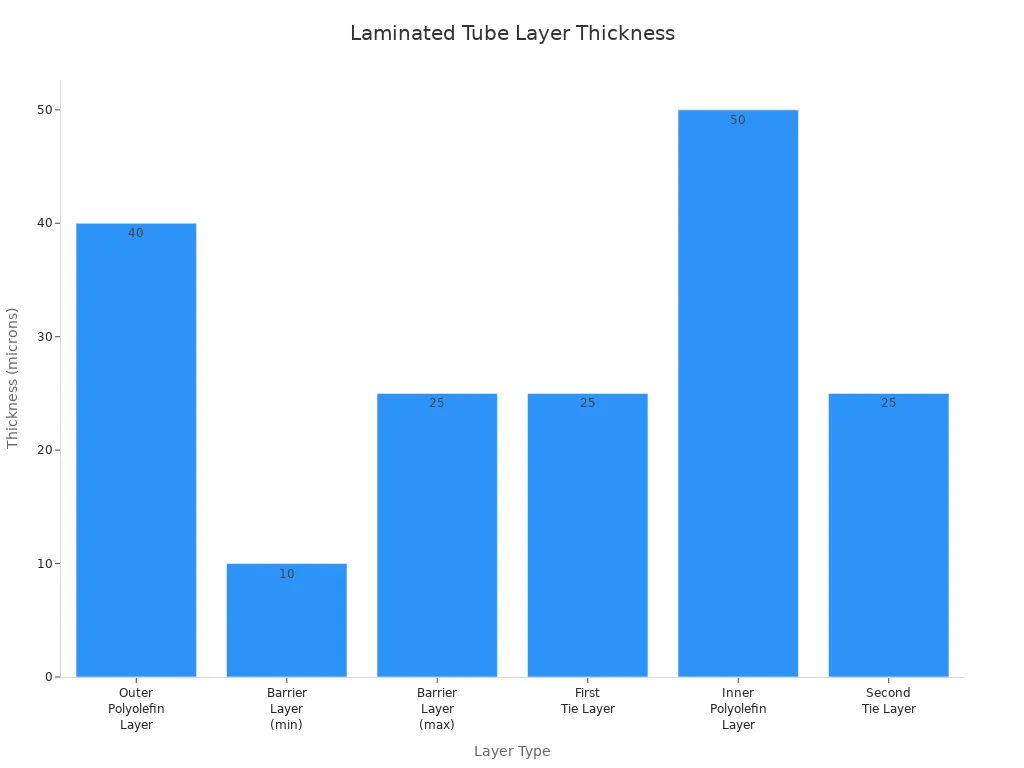

Laminated tubes are made with many layers. Each layer does something important. The outside layer uses polyolefin. This makes the tube look shiny and smooth. The barrier layer is made from aluminum or EVOH. It stops air and light from getting in. Tie layers hold all the layers together. The inside layer touches the product and keeps it safe.

| Layer Type | Thickness Range (microns) |

|---|---|

| Outer Polyolefin Layer | 40 |

| Barrier Layer | 10 to 25 |

| First Tie Layer | 25 |

| Inner Polyolefin Layer | 50 |

| Second Tie Layer | 25 |

This design makes the tubes strong. They do not break or tear easily. The package feels smooth and seals well. Nothing leaks out.

Tip: The layers help your product stay fresh and safe longer.

Barrier Properties

Laminated tubes keep your products safe from things that spoil them. The barrier layer blocks oxygen, water, and light. For example, ABL tubes use aluminum. This keeps out light and air. It is good for medicine and creams. PBL tubes use EVOH film. This keeps oxygen out, so your product stays good.

Laminated tubes work better than regular plastic tubes. They keep out more air and water. This helps your toothpaste, cream, or food stay fresh and work well.

| Industry | Impact on Shelf Life |

|---|---|

| Food & Beverage | Stops moisture and oxygen, so sauces and dairy stay good. |

| Pharmaceutical | Keeps medicine safe by blocking moisture, oxygen, and light. |

| Personal Care | Makes products last longer, which is good for beauty brands. |

Flexibility

Laminated tubes bend without breaking. This is better than aluminum tubes. Aluminum tubes can dent or crack. Plastic tubes bend too, but do not protect as well.

- You can squeeze out creams and gels easily.

- The tube goes back to its shape after you use it.

- Laminated tubes fit in bags and pockets.

You can use almost all the product inside. The tube keeps the product safe from air each time you open it.

Design

Laminated tubes come in many shapes and sizes. Machines make them fast and in different ways. Bright colors and clear logos are printed right on the tube. This helps your product stand out.

- Automation makes tubes quickly and with fewer mistakes.

- Fast machines help brands fill big orders.

- Laminated tubes use many materials, so you get the right tube.

- Good printing makes your brand look nice.

- Bright colors and designs get your attention.

- Eco-friendly printing helps the planet.

Safety

Laminated tubes follow strict safety rules. They have strong seals and tamper-evident parts. This shows your product is fresh and safe. Many tubes meet rules like ISO, FDA, and child-resistant standards.

| Certification/Standard | Description |

|---|---|

| ISO | Checks for quality and safety. |

| FDA | Makes sure food and drug packaging is safe. |

| ISO 8317 | Child-resistant packaging certification. |

| ASTM D3475 | Safety and performance rules for packaging. |

| CPSC 16 CFR §1700 | U.S. rules for child-resistant packaging. |

| EN ISO 8317 | European child-resistant packaging rule. |

| CRC c. H-3 | Canadian packaging safety rule. |

| ISO 15378 | Checks packaging for medicine products. |

- Tamper-proof designs keep you safe from harm.

- Child-resistant features protect young kids.

- Strong seals stop germs, air, and water from getting in.

Laminated tubes keep your creams, medicines, and foods safe. You can trust the product inside is clean and protected.

Benefits

For Brands

You want your products to stand out and stay protected. Laminated Tubes help you do both. These tubes offer cost savings compared to rigid packaging. They weigh less, so you spend less on shipping and storage. You can move more products at once, which lowers your logistics costs.

| Aspect | Laminated Tubes | Rigid Packaging |

|---|---|---|

| Cost Efficiency | Yes | No |

| Weight | Lightweight | Heavier |

| Transportation Ease | Easier | More Difficult |

| Logistics Cost Reduction | Yes | No |

| Versatility | High | Limited |

You can also keep your products fresh for longer. Laminated Tubes protect sensitive ingredients from light and air. This is important for creams, sunscreens, and medicines. Your products stay stable and safe, which helps you meet strict rules for quality.

You can make your brand look unique. You can choose special colors, shapes, and designs. Digital printing lets you add bright graphics and clear logos. This helps your product catch the eye on store shelves. Many brands use these tubes to create a strong identity and attract more buyers.

- Custom designs help your brand stand out.

- Bright colors and unique shapes grab attention.

- Advanced printing makes your logo look sharp and clear.

- You can meet the needs of both local and global markets.

Note: Laminated Tubes help you save money, protect your products, and build a strong brand image.

For Consumers

You want packaging that is easy to use and keeps your products safe. Laminated Tubes make this possible. You can squeeze out just the right amount of cream or gel. The tube stays clean and does not break easily. You can carry it in your bag without worry.

- Easy to squeeze and control how much you use.

- More hygienic because you only touch what you need.

- Lightweight and portable for travel or daily use.

- Less likely to break or leak.

You also get products that last longer. The special layers in Laminated Tubes keep out air and light. Your creams, medicines, and foods stay fresh and safe for longer. You can trust that what you buy will work well until the last drop.

Tip: Choose products in Laminated Tubes for better convenience and longer-lasting quality.

Environmental Impact

You care about the planet and want packaging that is better for the environment. Laminated Tubes now use new materials and designs to help reduce waste. Some tubes use recycled plastics or bio-based materials made from plant oils. These options help lower the use of new plastic.

- Some tubes are fully recyclable and still protect your products.

- New designs use less plastic but keep the tube strong.

- Bio-based plastics come from renewable sources like plant oils.

- Tubes with recycled content help cut down on waste.

Manufacturers keep working on ways to make Laminated Tubes even greener. You can find tubes that use up to 50% recycled plastic. Some tubes are lighter, which means less plastic is needed. These changes help lower the carbon footprint of packaging.

Note: When you choose products in Laminated Tubes, you support brands that care about the environment.

Applications

Cosmetics

Laminated tubes are used a lot in cosmetics. Brands put creams, lotions, gels, and toothpaste in them. Xinfly Packaging makes tubes for fancy skincare and beauty items. These tubes keep formulas safe from air, water, and light. The tubes are soft and easy to hold. They do not break or crack easily. Printing on the tubes is bright and clear. This helps your favorite brands get noticed.

| Feature | Description |

|---|---|

| Barrier Protection | Shields formulas from oxygen, moisture, and light. |

| Flexibility | More flexible than pure aluminum, providing better usability. |

| Durability | Maintains structural integrity under various conditions. |

| Cost-Effectiveness | Generally cheaper than pure metal tubes while offering similar protection. |

| Printing Capability | Allows full-color printing directly on the tube’s surface. |

- These tubes are great for creams and gels.

- Plastic and aluminum together give better safety.

- Your products stay fresh for a longer time.

Tip: Pick cosmetics in laminated tubes for more safety and a cool look.

Pharmaceuticals

Laminated tubes are used for medicine, ointments, and gels. Xinfly Packaging makes special tubes that follow strict safety rules. These tubes have layers that keep medicine safe from water, air, and germs. Some tubes have child-safe nozzles for extra safety. Laminated tubes help you use the right amount and keep it clean.

- Tubes follow FDA and ISO rules.

- They keep medicine safe from air and water.

- You can use just what you need and waste less.

Note: Laminated tubes help your medicine stay safe and work well until the end.

Food

Laminated tubes are used for sauces, dressings, pastes, and condensed milk. Xinfly Packaging makes tubes for many food brands. These tubes have thin layers that block air, water, and light. This keeps food fresh and stops it from going bad. You can squeeze out only what you need, and the tube stays clean.

| Layer Composition | Benefits |

|---|---|

| Multiple Thin Layers | Provides excellent barrier properties against oxygen, moisture, light, and contamination. |

| High-Quality Printability | Allows for aesthetic appeal and branding through various printing techniques. |

- Tubes help keep vitamins and antioxidants strong.

- Your food tastes fresh and lasts longer.

Tip: Laminated tubes make food safer and easier to use.

Industry

Laminated tubes are used for things like glue and paint. Xinfly Packaging makes tubes for many uses in factories. Companies pick laminated tubes because they keep products safe from dirt and light. Tubes are simple to use and cost less than other packages.

| Reason for Choosing Laminated Tubes | Description |

|---|---|

| Sustainability | The growing demand for sustainable packaging solutions is a key factor driving market growth. |

| Product Integrity | Laminated tubes protect the contents from contamination and degradation. |

| Cost-Effectiveness | They are affordable compared to traditional packaging options. |

| Convenience | Tubes are easy to use and versatile for various products. |

- Tubes have tight lids to keep things safe.

- You can use the product without touching it.

Note: Laminated tubes help keep industrial products safe and easy to use.

Laminated tubes help keep your products safe and clean. They are simple to use and easy to carry. Brands pick them because they cost less and protect well. These features help you every day in many ways:

| Advantages of Laminated Tubes |

|---|

| Simple to use |

| Easy to carry |

| Keeps products safe and fresh |

| Stops water, air, and light |

| Harder to open by mistake |

| Stays clean and hygienic |

Laminated tubes are still important as people want greener packaging. New ideas like smart packaging and better printing make them even more useful in the future.

Laminated Cosmetic Tubes – Frequently Asked Questions

Understand ABL vs. PBL structures, barrier performance, print quality, recyclability, cost, typical uses, and how to choose specs for your formula.

1) What is a laminated cosmetic tube?

2) What’s the difference between ABL and PBL?

3) When should I choose ABL over PBL?

4) Are laminated tubes recyclable?

5) How do laminated tubes compare with extruded PE tubes?

6) What printing and finishes are available?

7) What sizes and diameters can I get?

8) Which caps and closures pair with laminated tubes?

9) How are laminated tubes sealed and tested?

10) What affects the cost of laminated tubes most?

11) What are typical MOQs and lead times?

12) Any claims & labeling tips?

Ready to customize your packaging? Contact our team for detailed pricing, MOQ flexibility, and fast production samples.